Description

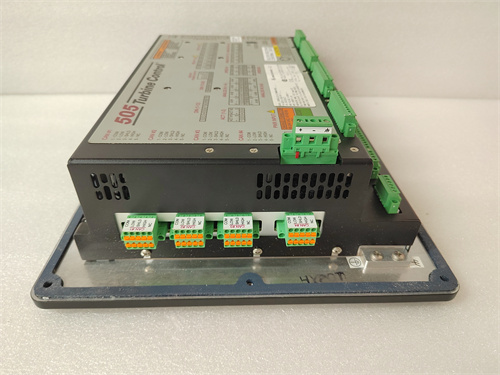

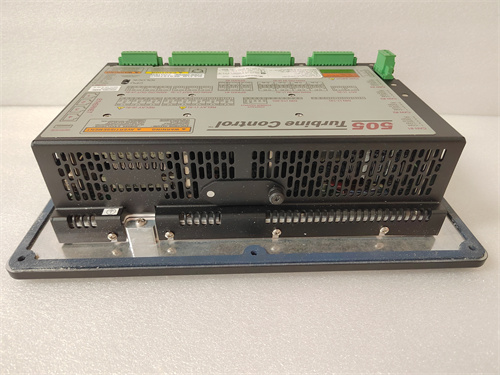

WOODWARD 8200-1300 is an important process control module or speed regulator produced by Woodward.The following is a detailed introduction to the product:

1.Product Overview

WOODWARD 8200-1300 is a digital control device designed by Woodward for steam turbines and other rotating equipment.It is a digital speed regulator in the 505 turbine control series with high reliability and accuracy,suitable for various industrial automation and control tasks.

WOODWARD 8200-1300

2.Technical Specifications

Input voltage:LVDC(18~32 Vdc),in line with standard power supply requirements.

Operating temperature:-30°C to+70°C(with display),suitable for a wide range of industrial environments.

Storage temperature:-30°C to+70°C(recommended 0°C to 40°C),to ensure the stability of the product for long-term storage.

Screen size:8.4 inches,providing clear graphic display and operation interface.

Protection level:standard IP20,pollution level 2,overvoltage category 3,ensuring the electrical safety and reliability of the product.

3.Functional features

Versatility:WOODWARD 8200-1300 has multiple functions and is suitable for different types of process control and automation tasks.It can control single-stage or two-stage split-range actuator steam turbines and be integrated into the automation control system to achieve intelligent control of the entire industrial process.

Control algorithm:Provides a variety of control algorithms,such as PID(proportional integral differential)control,to achieve precise process control.These algorithms can be selected and adjusted according to actual application requirements.

WOODWARD 8200-1300

Data acquisition and monitoring:It can collect data generated by sensors and equipment for real-time monitoring and control.At the same time,it also has equipment health monitoring functions to help monitor the health of equipment,detect potential problems in advance and take maintenance measures.

Real-time performance:Supports real-time operation,can respond to input signals within milliseconds,and ensure the speed and accuracy of the system.

Communication interface:It has a variety of communication interfaces,such as Ethernet,serial port,Modbus,etc.,for data exchange and coordinated control with other devices or systems.

Programmability:Supports programmable functions,allowing users to customize settings and logic control according to application requirements,improving the flexibility and scalability of the system.

IV.Application scenarios

Engine control:8200-1300 speed governors can be used in engine control systems to ensure that the engine operates within a safe,stable and efficient speed range.

Turbine speed regulation:In turbines and other rotating equipment,speed governors can be used to adjust and control the operating speed of the equipment to meet specific working requirements.

Generator speed regulation:Used for speed regulation of generator sets to ensure that the generators in the power system can provide stable power output as required.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water supply”

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: