Description

Vibro-meter VM600 CMC16 is a combustion state monitoring module.The following is a detailed introduction to the product:

1.Product Overview

The Vibro-meter VM600 CMC16 combustion state monitoring module is a key device for monitoring the combustion process.It uses advanced sensors and algorithms to monitor various parameters in the combustion process,such as temperature,pressure,vibration,etc.in real time to ensure the stability and safety of the combustion process.

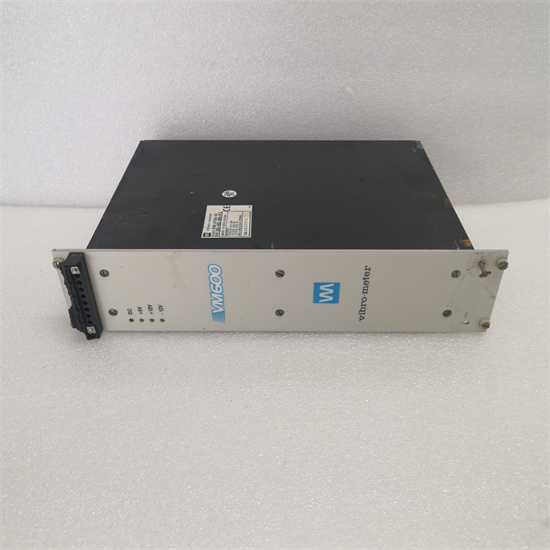

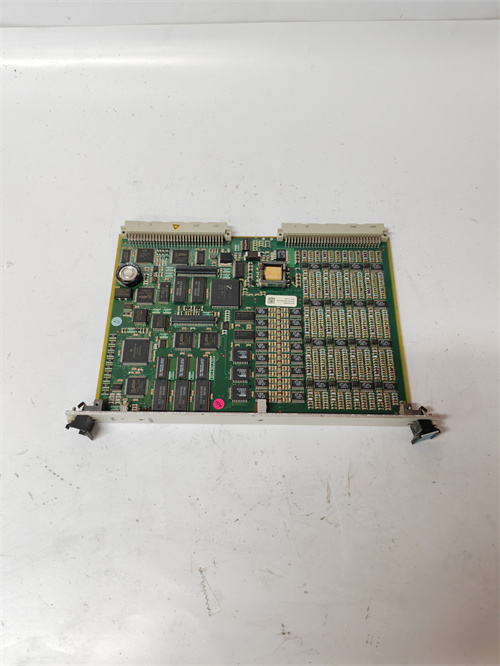

Vibro-meter VM600 CMC16

2.Main Features

High-precision measurement:

VM600 CMC16 uses high-precision sensors and measurement technology to accurately measure various parameters in the combustion process and provide reliable data support for combustion control.

Real-time monitoring:

This monitoring module can monitor the state of the combustion process in real time,detect abnormal conditions in time,such as unstable combustion,flame extinction,etc.,and provide operators with timely warnings and troubleshooting guidance.

Intelligent analysis:

VM600 CMC16 uses advanced algorithms and data analysis technology to perform intelligent analysis of the combustion process,provide combustion optimization suggestions and fault diagnosis information,and help operators improve combustion efficiency and equipment reliability.

Easy to integrate:

The monitoring module uses standardized interfaces and communication protocols,which facilitates integration and connection with other industrial automation systems to achieve remote monitoring and data sharing.

III.Technical specifications

Channel configuration:

Provides 16 dynamic channels and 4 tachometer channels,with up to 20 processing outputs per dynamic channel and each dual channel(12 per XMC16).

Data acquisition:

Adopts 24-bit data acquisition technology with high signal-to-noise ratio data processing capabilities.

High-resolution FFT of up to 6400 lines per 500 milliseconds.

Software compatibility:

Designed to operate with VibroSight®software.

Other specifications:

Brand:Vibro-meter.

Origin:Switzerland.

Voltage:24V.

Current:100-400A.

Weight:2KG.

Vibro-meter VM600 CMC16

IV.Application areas

Power plants and power industry:

Used to monitor the combustion status of equipment such as boilers and gas turbines to improve efficiency and ensure safe operation.

Chemical industry:

Used to monitor combustion efficiency and prevent incomplete combustion in the high temperature and high pressure environment generated during the combustion process.

Oil and gas industry:

Used to optimize the combustion process and improve energy efficiency.

Pharmaceutical industry:

Used to monitor the combustion state and ensure combustion safety and compliance during the production process.

Steel and metal processing:

Used to monitor and control the combustion state during high-temperature smelting and combustion to ensure the stability and efficiency of the smelting process.

Environmental protection:

Used to ensure that combustion emissions comply with environmental regulations and standards.

Industrial boilers and heating systems:

Used to monitor and optimize the combustion process of various industrial boilers and heating systems to improve system efficiency.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: