Description

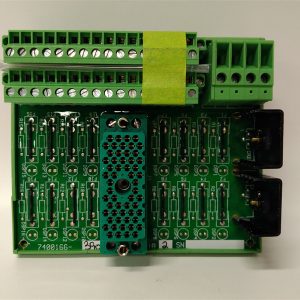

TRICON 3009,specifically refers to the 3009 Tricon controller produced by Triconex,which is a highly fault-tolerant programmable and process control technology product that uses an enhanced main processor(UMP)module.The following is a detailed introduction to TRICON 3009:

I.Product Overview

As a type of Tricon controller,TRICON 3009 has attracted much attention for its excellent reliability and availability.It is particularly suitable for industrial environments that require high fault tolerance and safety,such as refineries,petrochemical/chemical plants,power plants,and offshore platforms.

II.Main Features

Triple-mode redundant structure(TMR):

TRICON 3009 provides a triple-mode redundant structure with three identical sub-circuits,each of which performs an independent degree of control.This design ensures that the system can continue to operate when a single component fails,improving the overall reliability of the system.

High fault tolerance:

The controller can endure harsh industrial environments and maintain stable performance under various conditions.Both its hardware and software designs have been rigorously tested and verified to ensure reliable control under various fault conditions.

Field installation and online repair:

TRICON 3009 can be installed in the field,and can be installed and repaired online at the module level without disturbing the field wiring.This greatly reduces downtime and maintenance costs.

Flexible I/O module support:

Supports up to 118 I/O modules(analog and digital)and optional communication modules.These modules can be connected to Modbus master and slave devices,or to Foxboro and Honeywell distributed control systems(DCS),and external hosts in TCP/IP networks.

Remote I/O capability:

Remote I/O modules up to 12 kilometers away from the mainframe can be supported,which makes TRICON 3009 more flexible and convenient in large industrial applications.

Windows NT-based programming software:

Developing and debugging control programs using Windows NT system-based programming software enables engineers to perform programming and debugging work more conveniently.

Comprehensive online diagnostic and repair capabilities:

Providing comprehensive online diagnostic and repair capabilities allows engineers to perform routine maintenance when Tricon is started and running without interrupting the control process.In addition,”hot standby”support is provided for I/O modules,which can be used in certain emergency situations where services cannot be provided in time.

III.Typical Applications

Emergency Safety Shutdown(ESD):

TRICON 3009 provides continuous protection in safety-critical devices in refineries,petrochemical/chemical plants,and industrial processes.It can monitor power plant trip signals and take shutdown measures when abnormal conditions occur.

Boiler Control:

Integrates boiler protection from abnormal conditions,safety interlocks for startup and shutdown,and flame safety applications.A single integrated Tricon system replaces separate non-integrated components,improving productivity and safety.

Turbine Control:

Control and protect gas turbines or steam turbines with high integrity and safety.The continuous operation of the Tricon controller provides maximum availability and implements speed control,startup and shutdown sequences in a single integrated system.

Offshore Platform:

Provides continuous availability and reliability for offshore platforms.Enables online replacement of faulty modules and automatically manages faults in modules,field wiring,and sensors.

IV.Summary

TRICON 3009 is highly regarded for its high fault tolerance,safety,and versatility in a variety of critical applications.It provides comprehensive online diagnosis and repair capabilities,as well as flexible I/O module support and remote I/O capabilities,allowing engineers to more conveniently perform system maintenance and expansion.In addition,its Windows NT-based programming software also makes programming and debugging more convenient.TRICON 3009 is widely used in emergency safety shutdown,boiler control,turbine control and offshore platforms,providing reliable control and protection for industrial processes.

TRICON 3009

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: