Description

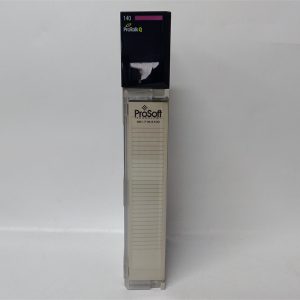

PROSOFT PTQ-PDPMV1 is a high-performance network communication processor module.The following is a detailed introduction to the module:

1.Product Overview

PROSOFT PTQ-PDPMV1 is a network communication processor module developed by PROSOFT for industrial automation.Based on the Quantum processor platform,this module provides powerful communication interfaces and data processing capabilities,and is suitable for various complex industrial automation control systems.

2.Main Features

PROFIBUS DPV1 Master Support:

This module supports PROFIBUS DPV1 master function and can communicate with slave devices that support PROFIBUS DPV0/V1 protocol.

Supports transmission of non-cyclic parameter data via Class 1 or Class 2 DPV1 services.

High-speed data transmission:

Adopts cross-backplane high-speed data transmission technology to provide fast data update time.

Supports all standard baud rates,up to 12Mbits/s,and can automatically detect baud rates at all valid PROFIBUS DPV1 rates.

Easy to configure and manage:

Equipped with ProSoft Configuration Builder software,it provides an easy-to-use drag-and-drop bus view configuration interface.

PROSOFT PTQ-PDPMV1

Supports online slave diagnostics,can monitor/modify process data and DPV1 acyclic data.

Rugged and reliable:

The module is ruggedly designed for use in a variety of harsh industrial environments.

Certified by the PROFIBUS Trade Organization(PTO),ensuring product reliability and compatibility.

Extended functionality:

Supports extended diagnostic data,alarm indication and confirmation processing,multicast and broadcast messages(DPV1).

Includes PROFIBUS DPV1 Master FDT(Field Device Tool)Communication DTM(PROFIBUS comDTM)software for connecting any compatible FDT software container,FDT device DTM and applicable PROFIBUS slave devices.

Hot standby function:

Compliant with UnityHEC hot standby function specification.

Supports up to 6 PTQ-PDPMV1 modules per rack(hot standby implementation supports up to 4 modules).

Compatibility:

Compatible with all common Quantum programming software packages,including Concept(2.6 or later),Unity Pro(2.2 or later),ProWORX(2.20 or later).

The supported Quantum data types include 3x and 4x.

PROSOFT PTQ-PDPMV1

3.Application Fields

The PROSOFT PTQ-PDPMV1 module is widely used in various fields that require high-performance network communication and industrial automation control,such as petrochemical,electric power,manufacturing and other industries.It can provide stable,reliable and efficient communication and data processing capabilities for industrial automation control systems.

4.Configuration and Use

Install the configuration software:

The ProSoft Configuration Builder(PCB)software must be installed to configure the module.The software can be downloaded from the ProSoft Technology website or installed from the product CD-ROM.

Connect the module:

The module has one serial port and one Ethernet port.When connecting to the module for configuration for the first time,you can use the provided modem to connect to the serial port of the module.

For hot standby systems,the Ethernet port must be connected for master-slave status checks and standby DP master buffer updates during hot standby switching.

Configuration parameters:

The Ethernet port can be used to change module configuration,diagnostics and bus monitoring functions.

Configuration parameters include input and output start register parameters,Profibus IO parameters related to slaves,etc.

Download configuration:

After configuration is completed,the updated project file needs to be downloaded to the module.When downloading the configuration to the module,the CPU must be in”STOP”state.

For a dual-machine hot standby system,the download process must be performed twice,and ensure that the two HSBY modules are connected together and allow the PCB to download the configuration to both modules.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: