Description

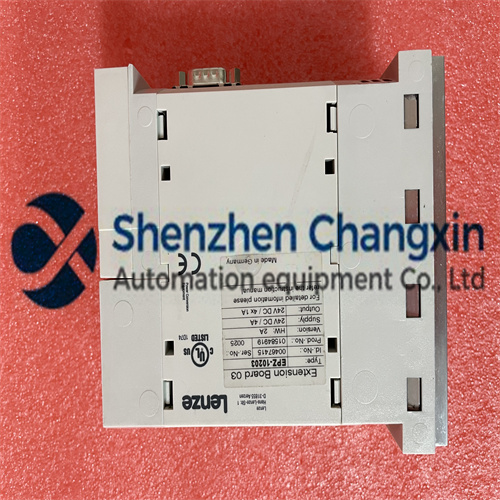

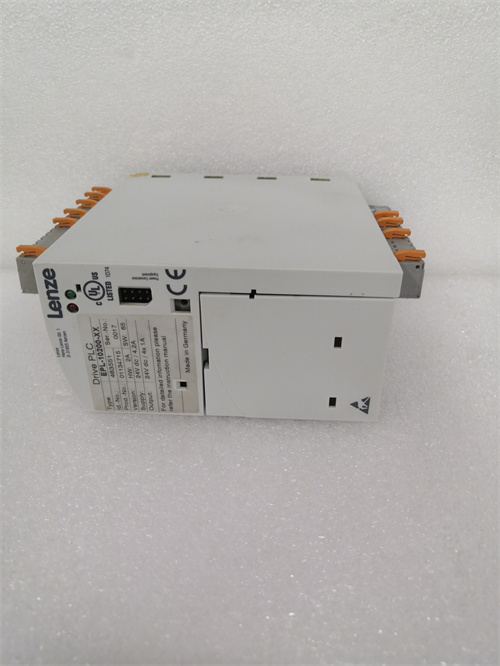

LENZE EPL10200-W is a high-performance servo drive designed to meet the needs of various industrial applications.The following is a detailed introduction to the product:

1.Product Overview

The LENZE EPL10200-W servo drive has become a popular choice in the field of industrial automation due to its powerful control functions,safety features,compact design,user-friendly interface and wide range of communication options.Whether it is a conveying system,pump,fan or mixer,it can provide reliable and efficient solutions.

2.Main Features

Powerful control function:

High-performance control algorithms are used to ensure the accuracy and smoothness of motor control.

The automatic tuning function makes the debugging process easy and fast,improving work efficiency.

Safety:

With the safe torque off function,the safety of operators and mechanical equipment is improved.

Compact and space-saving design:

The compact design makes it easy to integrate into existing industrial systems without taking up too much space.

LENZE EPL10200-W

User-friendly interface:

Equipped with a user-friendly interface,it makes operation simple.

Various software tools are provided to make the programming process easier,and users can quickly create customized motion control programs.

Wide range of communication options:

In order to meet the needs of different industrial networks,LENZE EPL10200-W provides a wide range of communication options,allowing it to be seamlessly integrated into various industrial networks.

3.Electrical and mechanical parameters

Electrical parameters:

It has a stable input voltage range and continuous/peak output current.

Mechanical parameters:

It is moderately sized and lightweight,suitable for use in a variety of scenarios.

4.Environmental parameters

LENZE EPL10200-W can operate in a wide temperature range and can operate stably under a certain relative humidity,which ensures its reliability and stability in various industrial environments.

LENZE EPL10200-W

5.Application scenarios

LENZE EPL10200-W servo drives are widely used in the field of industrial automation,including but not limited to conveying systems,pumps,fans,mixers and other scenarios.Its powerful functions and adaptability enable it to meet the needs of various complex and diverse industrial applications.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: