Description

Product description

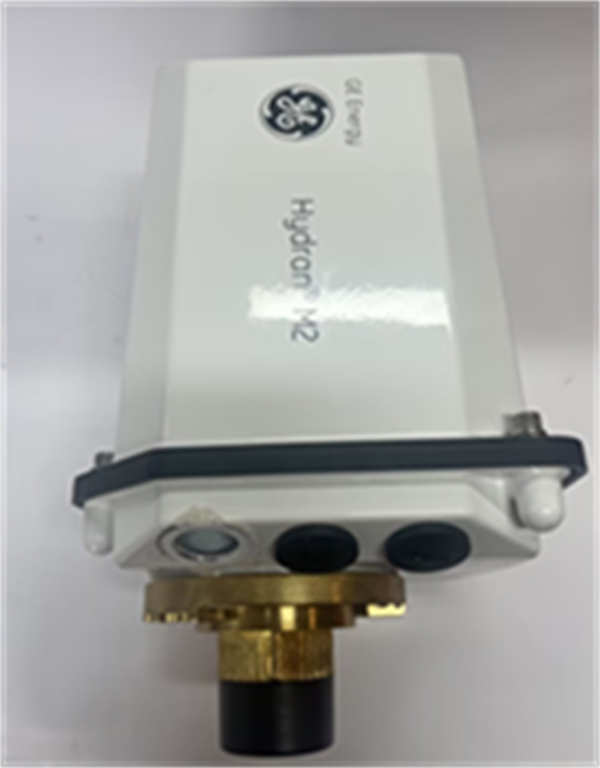

The HYDRAN M2 GE transformer monitoring device is designed to monitor and protect transformers by providing real-time data on key parameters.

trait

The hydrogen sensor responds 100%to hydrogen(a common fault gas)

The composite gas sensor is 100%responsive to hydrogen and is also sensitive to carbon dioxide(superheated paper insulators).

Up to 4 input or output cards can be selected

Extensive communication methods and protocols.

Standard RS485 output.TCP/IP Copper or optical fiber Optional

Vacuum gas extraction membrane.

Built-in temperature control system.

Complete system self-test and self-diagnosis.

Record data and major events for up to a year.

User-friendly client/server graphical user interface software.

The Hydran M2 is an economical,powerful,all-in-one transformer monitoring device that allows power grids and other users to deploy monitoring of numerous transformers and benefit from its advanced features.

The Hydran M2 Early Failure Alarm model monitors early failure of transformers and other oil-immersed equipment with in-line failure gas and humidity sensors.Additional digital and analog inputs allow monitoring of other transformer variables.The new transformer model expands the monitoring and asset management capabilities of the Hydran M2,which provides more decision-making assistance to equipment operators and maintenance personnel.

Transformers are critical and expensive components of the power grid,and knowing their health is critical to having a reliable network.When the insulation system of the transformer is stressed too much,gas dissolved in the oil will be produced.Dissolved gas analysis in oil(DGA)is recognized as the best indicator of fault development.

™MM2 is a continuously in-line dissolved gas in oil and moisture monitoring device used to alert transformers to failure.It provides critical monitoring information and minimizes the risk of unplanned downtime

By connecting additional sensors,such as top and bottom tank oil temperature,transformer load,or ambient temperature,additional information can be obtained and compared with DGA and humidity values for a deeper analysis of the transformer’s condition.

This rich data can not only be transmitted raw using M2’s wide range of communication options,but can also be converted into useful information by on-board calculations based on the IEEE®standard’s mathematical model of the transformer to provide further conditional information.

The Hydra M2 is a compact,permanently installed,in-line transformer monitoring device that alerts workers to fault conditions.It continuously monitors the combined value of various faulty gases(in ppm)or only the hydrogen value(depending on the sensor purchased).In addition,it can track the moisture in the oil(readings are in%RH and ppm).

With the addition of additional sensors,the Hydran M2 can also calculate a mathematical model of the transformer according to IEEE®and IEC®standards to provide more information about the transformer’s performance.

advantage

Real-time hydrogen or compound fault gas monitoring system

Measurement of moisture in oil

Ability to integrate additional sensors(load,oil temperature…)

Optional processing of transformer mathematical models based on IEC/IEEE standards

Easy to install on a single valve.

There are no moving parts,no pumps,and no additional piping required.

No field calibration required.

Local and remote alerts are set at predefined levels.

Application field

The HYDRAN M2 GE transformer monitoring equipment is widely used in power generation,transmission and distribution systems.Industrial plant;Renewable energy facilities;Let’s wait.

HYDRAN M2 GE

HYDRAN M2 GE

HYDRAN M2 GE

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: