Description

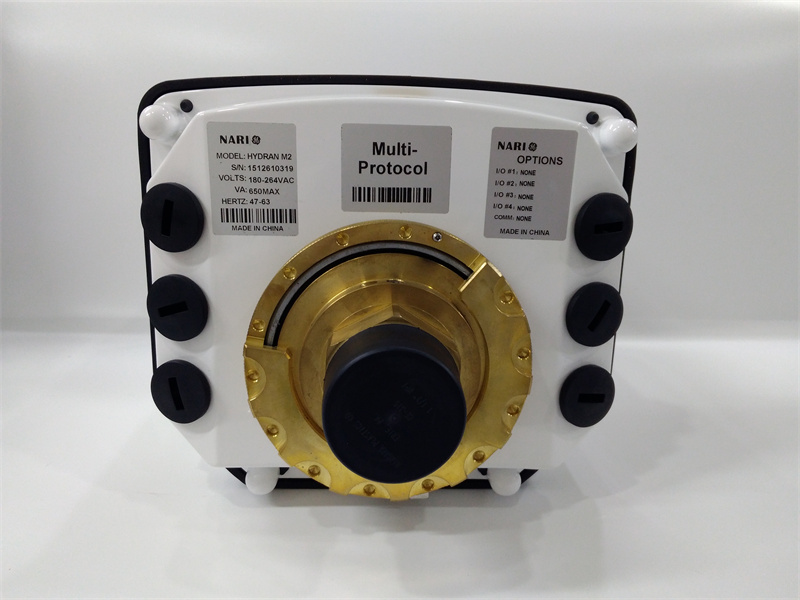

HYDRAN M2 is a product of GE.

Product Name: HYDRAN M2

Product Details:

The HYDRAN M2 is a compact, permanently installed, on-line transformer monitoring device.

Alerts personnel to developing fault conditions.

Continuously monitors synthetic (in ppm) or hydrogen only (depending on the sensor purchased) values of various fault gases.

Tracks moisture in the oil (in %RH and ppm readings).

By adding additional sensors, the HYDRAN M2 can also calculate mathematical models of the transformer according to IEEE and IEC standards to provide more information about transformer performance.

Features:

Real-time fault gas and humidity measurement system in oil.

Gas extraction membranes that do not allow vacuum.

Individual valve mounting, eliminating the need for additional pumps and moving parts.

Intelligent microprocessor based electronics.

Full system self-testing and self-diagnostics.

NEMA 4X (IP66) enclosure.

Digital display with flip screen control.

4 programmable relays for alarms.

1 self-test relay contact.

4 expansion I/O plug connectors, which need to be combined with the following boards: Isolated 4-20mA analog input card, Isolated dual channel digital input card, Isolated 4-20mA analog output card.

1 communication expansion plug connector: Ethernet 10-100baseT card, analog modem.

Local connection isolated RS-232 serial interface.

Isolated RS-485 serial interface for remote connection.

Supports DNP3 protocol (serial interface or TCP/IP).

Extended adjustable frequency data and event log.

Adjustable level and trend based alarm settings for gas, humidity, analog inputs and transformer model calculations.

Friendly client/server graphical user interface (GUI) allowing multi-client access via TCP/IP.

Areas of application: For all kinds of transformers, including power transformers, distribution transformers and industrial transformers.

Particularly suitable for the following environments: high temperature, high humidity, high corrosive environment; serious oil contamination, explosive environment; equipment running time, high importance of the equipment environment.

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: