Description

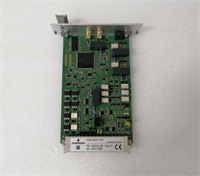

EMERSON A6500-UM is a universal monitoring module.The following is a detailed introduction to it:

1.Product Overview

The A6500-UM universal measurement card is a component of the AMS 6500 ATG mechanical protection system.It has the characteristics of high-precision measurement,intelligent fault diagnosis and multiple monitoring modes,which can help enterprises prevent equipment failures and improve production stability.The module is easy to integrate and operates stably in harsh environments.It is an important maintenance tool for industries such as petrochemicals and power.

2.Functional Features

High-precision measurement:A6500-UM uses high-precision sensors and advanced signal processing technology to accurately measure the vibration of the shaft.By monitoring vibration data in real time,users can understand the operating status of the equipment,detect abnormal conditions in time,and avoid equipment damage and production interruptions.

Multiple monitoring modes:Supports multiple monitoring modes such as absolute vibration,relative vibration,shaft eccentricity,shell piezoelectric vibration,thrust and rod position,differential and shell expansion,valve position,etc.These modes can be selected according to different equipment and application scenarios to meet the actual needs of users.

Intelligent fault diagnosis:With intelligent fault diagnosis function,it can identify potential fault modes,provide fault warning and fault diagnosis information through analysis and processing of vibration data.This helps users take corresponding maintenance measures in time to avoid the impact of equipment failure on production.

EMERSON A6500-UM

Easy to integrate and configure:A6500-UM has good integrability and configuration flexibility.It can be seamlessly integrated with other industrial automation systems to provide a unified monitoring and management platform.At the same time,the module also provides rich configuration options and parameter settings to meet the needs of different equipment and applications.

High reliability and stability:As a world-leading provider of industrial automation solutions,Emerson’s products have strict guarantees in terms of quality and reliability.A6500-UM has undergone rigorous production and testing processes to ensure stable operation in harsh industrial environments.

III.Technical specifications

Sensor input:Equipped with 2 sensor input channels(independent or combined,depending on the selected measurement mode),the most common sensors can be used,such as eddy current,piezoelectric(accelerometer or velocimeter),seismic(electrodynamic),LF(low-frequency bearing vibration),Hall effect and LVDT(used in conjunction with A6500-LC)sensors.

Digital Inputs and Outputs:Contains 5 digital inputs and 6 digital outputs.

Communication Interface:The measurement signal is transmitted to the A6500-CC Com card via the internal RS 485 bus and converted to Modbus RTU and Modbus TCP/IP protocols for further transmission to the host or analysis system.At the same time,the Com card can also communicate with a PC/laptop via the USB interface on the panel to configure the card and display the measurement results.

Analog Output:The measurement results can be output via 0/4-20mA analog outputs,which have a common ground and are electrically isolated from the system power supply.

Cabinet Space:Dual-channel,3U size,1-slot plug-in module,which reduces the cabinet space requirements by half compared to traditional four-channel 6U cards.

Standard Compliance:API 670 compliant,hot-swappable modules.

Other Features:Remotely selectable limit multiplication and trip bypass;front and rear buffering and proportional output;self-test functions include monitoring hardware,power input,hardware temperature,sensors and cables,etc.

EMERSON A6500-UM

4.Application Field

A6500-UM universal measurement card is widely used in rotating equipment monitoring in petrochemical,electric power,steel and other industries.It can provide important technical support and guarantee for equipment maintenance and management of enterprises,help users to timely discover potential equipment failures,and provide reliable early warning and protection mechanisms to ensure stable operation and safe production of equipment.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: