Description

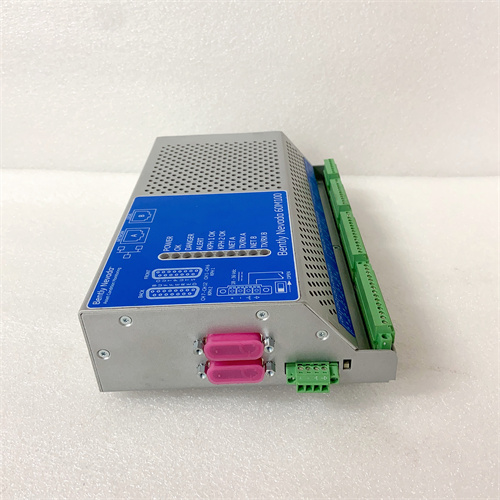

BENTLY 60M100-00 is a high-performance condition monitoring system and automation control module provided by Bently Nevada(now part of GE),which is widely used in the monitoring and protection of wind turbines and other critical rotating equipment.The following is a detailed introduction to the product:

I.Product Overview

As part of the condition-based maintenance system,BENTLY 60M100-00 uses advanced signal processing algorithms and machine operating status information to continuously and in real time monitor wind turbines.It can detect defects months before potential failures occur,thereby effectively reducing downtime and production losses.

II.Main Features

High-precision vibration monitoring:

The system is equipped with high-precision vibration sensors that can monitor the vibration velocity,acceleration,displacement,and vibration amplitude,frequency,and phase of the equipment in real time.

Through the precise collection of vibration data,users can timely understand the health status of the equipment,predict possible failures,and take appropriate maintenance measures.

BENTLY 60M100-00

Mechanical health status analysis:

The system can be used to analyze the mechanical health status of the equipment,including identifying potential problems such as bearing wear,imbalance,and looseness.

Advanced signal processing algorithms are able to extract dozens of measurements and health indices from each accelerometer point and customize them for specific bearing and gearbox characteristics.

Real-time data acquisition and processing:

The system has real-time data acquisition capabilities to ensure timely monitoring of equipment status.

At the same time,the system also has historical data storage capabilities,allowing users to store and retrieve vibration data for subsequent analysis and comparison.

Alarms and notifications:

The system can trigger alarms and notifications based on set thresholds to notify operators in time when equipment problems occur.

Alarms include various indicator lights(such as power LED,OK LED,danger LED and alarm LED)and user-programmable alarm comparison functions.

Remote access and multi-channel monitoring:

Some versions support remote access functions,allowing users to monitor equipment status from remote locations.

The system supports multi-channel monitoring and can monitor multiple channels simultaneously to cover multiple devices or multiple locations.

BENTLY 60M100-00

III.Technical specifications

Input power:minimum 18 V DC,maximum 36 V DC.

Current:maximum 1.7A;Surge current:maximum 2.7A(less than 5ms).

Input dynamic range:110dB fs=102.4ksps.

Signal-to-noise ratio:110dB fs=102.4ksps.

A/D conversion:Σ-Δ24-bit nominal.

Bandwidth:0 to 40kHz.

Operating temperature range:-40°C to+70°C(-40°F to 158°F).

Storage temperature range:-45°C to+85°C(-49°F to 185°F).

Relative humidity:0%to 95%(non-condensing).

IV.Application areas

BENTLY 60M100-00 is mainly used in the wind power industry for condition monitoring and fault warning of wind turbines.At the same time,it can also be used in other areas where monitoring and protection of critical rotating equipment is required,such as power plants,oil and gas industries.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water supply”

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: