Description

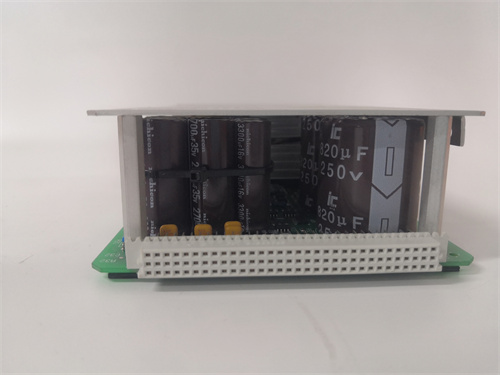

BENTLY 3500/15 127610-01 is a high-performance industrial system component.The following is a detailed introduction to the product:

1.Product Overview

BENTLY 3500/15 127610-01 is an important part of Bentley’s 3500 series industrial system,and is designed to provide reliable power support for online monitoring and protection systems designed for rotating mechanical equipment.This product adopts advanced technology and design,has excellent performance and stability,can work continuously for a long time,and ensure the stable operation of the entire monitoring system.

2.Main features

Power module design:

The 3500/15 power module is a half-height design that fits into a specific slot on the left side of the rack.

Provides a combination of AC and DC power supplies that accept a wide range of input voltages and converts them to voltages used by other 3500 series modules.

The rack can accommodate one or two power supplies,one as the main power supply and the other as a backup to ensure uninterrupted operation.

High performance and stability:

This module has excellent performance and stability,can work continuously for a long time,and provides accurate vibration monitoring for rotating mechanical equipment.

Highly compatible with other components of the Bently 3500 series(such as monitor modules,relay modules,etc.),it is easy to integrate into the entire monitoring system.

BENTLY 3500/15 127610-01

Easy maintenance and upgrade:

The design of the module takes into account the needs of easy maintenance and upgrade.Users can replace or upgrade the module through simple operations.

This ensures the continuous operation and performance improvement of the system and reduces maintenance costs.

Safety protection function:

The module has a complete safety protection function,which can issue an alarm in time when abnormal vibration is detected and take necessary protection measures.

This helps to prevent equipment damage or production accidents and ensure production safety.

III.Application field

BENTLY 3500/15 127610-01 is widely used in vibration monitoring and protection of various rotating mechanical equipment.These equipment include but are not limited to steam turbines,water turbines,fans,compressors,turbo expanders,motors and generators.By monitoring the vibration of the equipment in real time,users can promptly detect potential faults and problems and take corresponding measures to repair and prevent them,thereby ensuring the stable operation of the equipment and the safe production.

4.Technical Specifications and Parameters

(Specific technical specifications and parameters may change due to product versions and manufacturer updates,the following information is for reference only)

Part Number:3500/15 127610-01

Manufacturer:GE/Bentley

Series:Bentley 3500/15

Operating Temperature:-22 to 150°F(-30 to 65°C)

Humidity Range:95%,non-condensing

Input Frequency:47 to 63 Hz

Power Type:AC and DC Combination

Installation Location:Must be installed in the designated slot on the left side of the rack

BENTLY 3500/15 127610-01

5.Usage and Maintenance Recommendations

Installation:

Ensure that the module is properly installed according to the manufacturer’s guidelines to avoid damage or improper connection.

Before installation,check the appearance of the module and whether the connector is intact.

Configuration:

Correctly configure the software parameters of the module according to system requirements to ensure compatibility with other parts of the control system.

Use the tools or software provided by the manufacturer for configuration and debugging.

Maintenance:

Perform regular maintenance and inspection of the module,including cleaning and checking the contact status of the connector.

Pay attention to the indicator lights and alarm information of the module to detect and deal with potential problems in time.

Safety:

During operation and maintenance,comply with all relevant safety procedures and regulations.

Avoid replacing or repairing the module without powering off.

In summary,BENTLY 3500/15 127610-01 is a high-performance,stable and reliable industrial system component suitable for vibration monitoring and protection of various rotating machinery and equipment.By properly installing,configuring and maintaining the module,the stable operation of the equipment and the safe production can be ensured.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water supply“

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: