Description

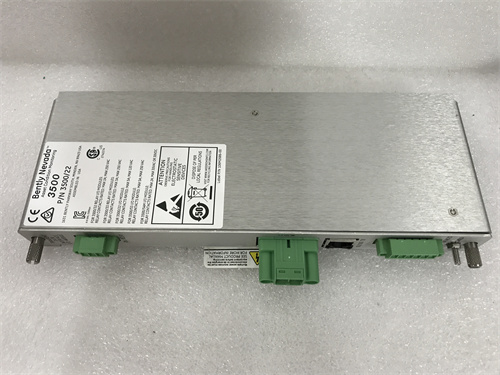

Bently 3500/22M,usually written as Bentley 3500/22M,is a transient data interface(TDI)module that belongs to the monitoring and control system product line of Bentley(now part of GE Detection&Measurement).The following is a detailed introduction to Bentley 3500/22M:

I.Main functions

The Bentley 3500/22M TDI module is the data exchange interface between the 3500 monitoring system and System 1 mechanical management software.It can continuously collect steady-state and transient dynamic(waveform)data and transmit the data to the host software via an Ethernet link for remote monitoring and analysis.The module is designed to collect static and dynamic data,especially to record high-resolution transient data,which is very useful for analyzing the operating status of mechanical equipment and diagnosing potential problems.

Bentley 3500/22M

2.Application Scenarios

The Bentley 3500/22M TDI module is suitable for a variety of industrial monitoring scenarios,including but not limited to:

Rotating equipment monitoring:It can be connected to M series monitors(such as 3500/40M,3500/42M,etc.)to provide key data for monitoring and diagnosis of various rotating equipment.

Mechanical protection:By continuously collecting steady-state and transient dynamic data,the TDI module helps implement effective mechanical protection measures to prevent failures and unexpected downtime.

Asset condition monitoring:The module can provide detailed information about the health of the machinery,helping maintenance teams to perform predictive maintenance and optimize asset performance.

Vibration analysis:The TDI module can capture vibration signals,which can be further analyzed to identify problems such as mechanical fatigue,imbalance,or bearing damage.

3.Technical specifications

The technical specifications of the Bentley 3500/22M TDI module may include but are not limited to the following(specific specifications may vary depending on product version or configuration):

Power consumption:Typically 10.5 watts.

Front panel interface:May include a USB-B interface.

Network Communications:Supports 100Base-FX fiber optic Ethernet,with TX/RX LED indicators to indicate that the module is communicating with other modules on the rack.

Configuration Status Indication:Has a CONFIG OK LED indicator to indicate whether the configuration of the 3500 rack is valid.

Data Collection Capability:Capable of collecting data at selected speed and time increments,supporting independent programming of increasing and decreasing speed intervals.Transient data collection can be initiated by detecting machine speed within one of two programmable windows.

Bentley 3500/22M

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: