Description

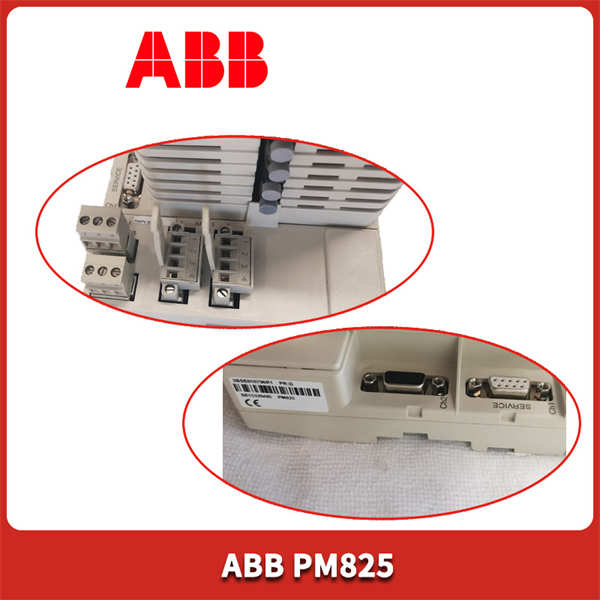

ABB PM825 Programmable Logic Controller

Product Description:

The ABB PM825 is a high-performance programmable logic controller (PLC) designed for industrial automation and control applications. It is a key component of ABB’s distributed control system, offering a range of features and capabilities for programming, configuring, and diagnosing industrial processes.

ABB PM825 Programmable Logic Controller

Product Parameters:

Processor: Based on the MC68360 microprocessor operating at 25MHz in 16-bit mode

Memory: 1024 KB FLASH for system and user application storage; 512 KB RAM for system and user application execution

User Interface: Includes DriveWindow, Modbus protocol panel, and printer

Power Supply: AC 80-240V

Operating Temperature: -30°C to +70°C

Product Specifications:

Versatile Connectivity: The PM825 can be used as a standalone controller or as part of the AF 100 (Advant Fieldbus 100) network

Advanced Programming: Supports AdvaBuild for Windows program suites, particularly Function Chart Builder, for easy programming, configuration, and diagnosis

High Performance: With its powerful processor and optimized memory configuration, the PM825 ensures fast and responsive control

User-Friendly Interface: The PM825’s user interface, including DriveWindow, Modbus protocol panel, and printer, facilitates easy operation, monitoring, and troubleshooting

ABB PM825 Programmable Logic Controller

Series:

The PM825 belongs to the PM800 series of controllers from ABB, which are specifically designed for industrial automation and control tasks. These controllers offer a range of features and specifications to meet different application requirements.

Features:

Versatile Connectivity: The PM825 supports various communication protocols, such as Modbus, Profibus, and Ethernet, allowing for seamless integration with different monitoring systems

High Precision: The PM825 provides high-precision measurement, ensuring reliable monitoring and control of electrical parameters in various applications

Data Logging: The controller can record important electrical data, enabling users to analyze and optimize power consumption and energy usage

Compact and Robust Design: The PM825’s compact size and sturdy components make it suitable for various industrial environments

Built-in Alarms and Notifications: Users can define custom thresholds for alarms and notifications, ensuring timely responses to electrical abnormalities

Functions:

The PM825 serves as a key component in industrial automation and control systems. It receives control signals, regulates motor parameters such as current, speed, and position, and implements precise motion control. This makes the PM825 suitable for a wide range of motion control applications, including mechanical arms, conveyor belts, and industrial machinery

Applications and Uses:

Industrial Automation: The PM825 is widely used in industrial automation systems to control and monitor various processes, ensuring efficient and reliable operation

Motion Control: The controller’s precision and performance make it ideal for motion control applications, such as mechanical arms and conveyor belts

Integration with Other Systems: With its support for multiple communication protocols, the PM825 can seamlessly integrate with other PLCs, DCS systems, servo systems, and robot systems, providing a unified control solution

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: