Description

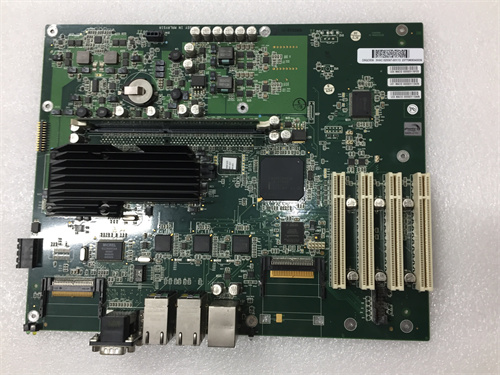

ABB DSQC639 is a computer unit,commonly used in industrial automation and robot control systems.The following is a detailed introduction to ABB DSQC639:

1.Basic attributes

Brand:ABB

Model:DSQC639

Origin:The origin may vary depending on the production batch and supply chain,but ABB,as a leading global supplier of industrial automation and electrical equipment,is widely recognized for its product quality and performance.

Warranty:Generally,a 1-year warranty period is provided,subject to the contract terms at the time of purchase.

2.Functional features

Support robot motion control:The DSQC639 computer unit can handle complex trajectory planning,coordinate transformation and motion instructions,enabling robots to perform precise movements in applications such as manufacturing,assembly and processing.

Production line automation control:On the production line,the unit can be used to control various equipment,conveyor belts,robotic arms,etc.to achieve automated production processes.

Data processing and communication:With data processing and communication functions,it can obtain data from sensors,equipment and other systems and transmit it to the upper control system for analysis and decision-making.

Logic control:allows the configuration of complex logic conditions and operation processes to meet different automation needs.

Equipment monitoring and diagnosis:can monitor equipment status,faults and alarms in real time to support predictive maintenance and troubleshooting.

ABB DSQC639

3.Technical details

Input/output wiring:

Input wiring should generally not exceed 30m,but if the environmental interference is small and the voltage drop is not large,the input wiring can be appropriately longer.

Input and output lines cannot use the same cable and should be arranged separately.

The width of the pulse signal that the programmable controller can accept should be greater than the time of the scan cycle.

Output terminal wiring:

It is divided into independent output and common output.

When the output relay or thyristor of the PLC is activated,the two output terminals of the same number are connected.

In different groups,output voltages of different types and voltage levels can be used.However,the outputs in the same group can only use power supplies of the same type and voltage level.

Input circuit and secondary circuit:

The primary circuit and the secondary circuit of the input end are isolated by photoelectric coupling.

The secondary circuit is equipped with an RC filter to prevent PLC malfunction due to input contact jitter or electrical noise from the input line.

ABB DSQC639

IV.Application Scenarios

ABB DSQC639 computer units are widely used in the field of industrial automation,including but not limited to the following scenarios:

Industrial robot control:used to control the movement and operation of industrial robots to achieve automated production.

Production line automation:control various equipment,conveyor belts,and robotic arms on the production line to improve production efficiency.

Data processing and communication system:collects data from sensors and other devices and transmits it to the upper control system for analysis and decision-making.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: