Description

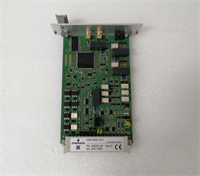

Product Description

The A6500-UM EMERSON monitoring module is a monitoring device used in industrial automation and process control systems.It is mainly used for real-time monitoring of various industrial parameters,such as temperature,pressure,flow rate,liquid level,etc.,and transmitting monitoring data to control systems or upper computer software for analysis and processing.

Features

High precision and reliability

Advanced data collection and analysis capabilities

User friendly interface for easy operation

Wide compatibility with different systems

The A6500-UM EMERSON monitoring module is a state-of-the-art device designed to monitor and analyze data in industrial applications.It provides advanced features and capabilities to ensure accurate and reliable monitoring of various systems.

The relative vibration mode of the shaft is used to provide the most critical rotating equipment in the factory to improve reliability.When used in conjunction with other CSI A6500 ATG monitoring modules,this feature can form a complete API 670 mechanical protection monitoring system.Its applications include steam turbines,gas turbines,compressors,and water turbines.

The main function of shaft relative vibration measurement is to compare the measured parameters with the alarm set values,drive alarms and relay outputs,and accurately monitor shaft relative vibration and protect equipment in a reliable way.

The relative vibration of the shaft includes a displacement sensor installed through the bearing housing or inside the bearing to rotate the shaft or monitor the target installed on the bearing housing to rotate the shaft as the monitoring target.

A displacement sensor is a non-contact sensor used to measure the position and motion of a shaft.Due to the installation of the displacement sensor on the bearing,the monitored parameters are called shaft relative vibration,which is the vibration of the shaft relative to the bearing housing.

Relative shaft vibration is an important measurement indicator used for prediction and protection monitoring on all sliding bearing machines.When the weight of the casing is much greater than that of the rotor,and it is expected that the bearing casing will not vibrate between 0 and normal operating speed,relative shaft vibration should be selected.When the mass of the bearing housing and rotor is close to equal,if the bearing housing is more likely to vibrate and affect the relative vibration reading of the shaft,absolute vibration measurement of the shaft is sometimes chosen.

Application field

The A6500-UM EMERSON monitoring module is widely used in industries such as manufacturing,energy,and automation to monitor and optimize system performance.

A6500-UM EMERSON

A6500-UM EMERSON

A6500-UM EMERSON

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: