Description

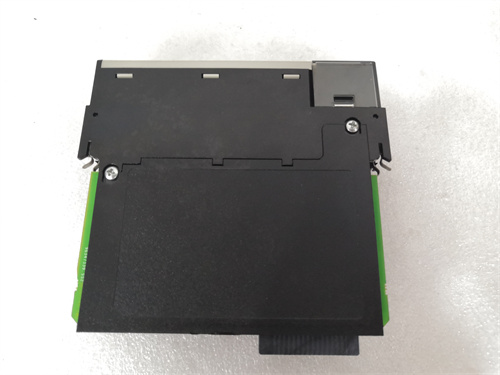

A-B 1756-ENBT is a communication module produced by Allen-Bradley(now part of Rockwell Automation)and is widely used in the field of industrial automation.The following is a detailed introduction to the module:

1.Main functions

Support EtherNet/IP protocol:

EtherNet/IP is an Ethernet-based industrial communication protocol developed by ODVA(Open Device Network Vendor Association).

The module supports high-speed,reliable and flexible data transmission to meet the communication needs of industrial automation systems.

Integration and compatibility:

The A-B 1756-ENBT module may be designed to integrate seamlessly with Allen-Bradley’s ControlLogix,CompactLogix or other series of PLCs.

It can be directly inserted into the slot of the PLC and configured and managed through the PLC’s programming environment.

A-B 1756-ENBT

Versatility:

The module supports multiple communication modes,including point-to-point communication,broadcast communication and multicast communication.

It also supports advanced communication functions such as real-time I/O data transmission,message transmission and explicit messaging.

Network configuration and management:

Users can easily configure and manage the module’s network settings through the corresponding network configuration tool or PLC programming software.

Including the settings of parameters such as IP address,subnet mask,gateway and DNS server.

Diagnosis and troubleshooting:

The module may have built-in powerful diagnostic functions to help users quickly locate and solve problems in network communication.

It may support real-time monitoring of network health,recording and querying of error logs,etc.

A-B 1756-ENBT

2.Industrial-grade design

In order to meet the demanding requirements of industrial automation environments,the A-B 1756-ENBT module may adopt industrial-grade design standards.

Including wide temperature operating range,anti-electromagnetic interference(EMI)and radio frequency interference(RFI)capabilities,as well as high reliability and long life.

3.Application scenarios

The A-B 1756-ENBT module is suitable for various industrial automation systems that require network communication.

Such as PLC control systems,remote monitoring systems,etc.in manufacturing,power systems,transportation systems,etc.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp / Wechat:+86 18150087953 / +86 18005022138

WhatsApp / Wechat:+86 18150087953 / +86 18005022138 Email:

Email: