Description

- Product Name:

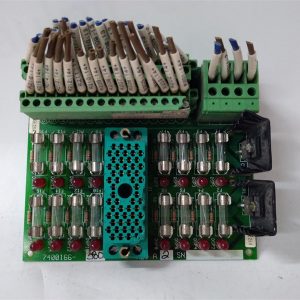

Triconex 8312 Safety Controller - Product Description:

The Triconex 8312 Safety Controller is a high-performance safety instrumented system (SIS) designed to provide critical safety monitoring and control for industrial applications. It is specifically engineered to prevent hazards and protect personnel, assets, and the environment in the event of potentially dangerous conditions. The 8312 Safety Controller offers a modular design, allowing for flexible configuration and expansion to meet unique safety requirements across various industries. - Product Parameters:

The key parameters of the Triconex 8312 Safety Controller are outlined below: - Modular Design: The controller features a modular architecture, enabling easy customization and scalability. This allows for the addition of additional modules as needed to meet specific safety requirements.

- Processing Power and Performance: The 8312 Safety Controller is equipped with powerful processors and advanced control algorithms to handle complex safety logic with high speed and precision.

- Redundancy and Fault Tolerance: The controller incorporates redundancy and fault tolerance features, including multiple processors and communication paths. This ensures continuous and reliable operation, even in the event of a component failure.

- Safety Integrity Level (SIL): The 8312 Safety Controller is designed to achieve Safety Integrity Levels (SIL) up to SIL 3, depending on the configuration and application requirements. It provides a high level of safety integrity to protect critical industrial processes.

- I/O Capacity and Flexibility: The controller supports a wide range of analog and digital input/output (I/O) modules, allowing for integration with various sensors, actuators, and other devices. This flexibility facilitates easy integration with existing systems and future expansions.

- Programming Environment: The 8312 Safety Controller offers a user-friendly programming environment, such as Tricon Studio, for configuring and maintaining safety logic. This environment simplifies the programming process, improves efficiency, and supports rapid development and deployment of safety-critical control applications.

- Communication Capabilities: The controller supports various communication protocols, enabling seamless integration with other industrial systems and devices. This allows for easy data exchange and integration with safety-related systems and plant-wide networks.

- Product Specification:

The detailed specifications of the Triconex 8312 Safety Controller include: - Operating Environment: Specified temperature range, humidity, and other environmental conditions for reliable and safe operation.

- Physical Dimensions: Precise dimensions, including length, width, and height, for easy integration into standard industrial racks or cabinets.

- Power Supply: Required power supply specifications, including voltage, current, and power consumption, for stable and reliable operation of the controller.

- Certifications and Compliance: The controller meets various industry standards and certifications, such as IEC 61508, ISA-S84.01, and SIL ratings. This ensures compliance with safety requirements and provides confidence in its performance.

- I/O Module Types and Quantities: Detailed specifications of the supported analog and digital input/output (I/O) modules, including their types, ranges, accuracies, and quantities.

- Communication Interfaces: The available communication interfaces and protocols supported by the controller, including their specifications, configuration options, and connectivity requirements.

- Programming Languages and Tools: The programming languages and tools supported for configuring and maintaining safety logic within the controller, including their features, requirements, and compatibility with other systems.

- For accurate and up-to-date information on the product name, description, parameters, and specifications of the Triconex 8312 Safety Controller, it is recommended to contact Honeywell or visit their official website. The product support team or sales representatives at Honeywell will provide you with detailed specifications tailored to your specific requirements.

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: