Description

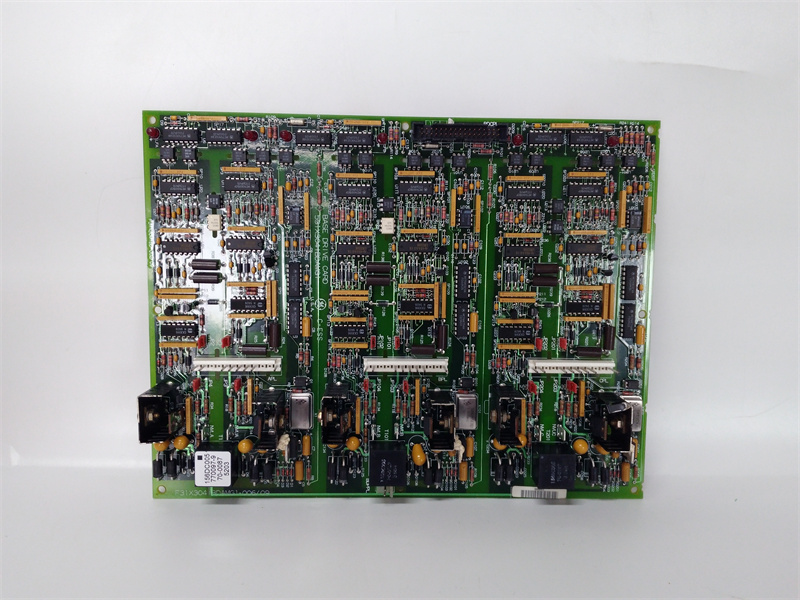

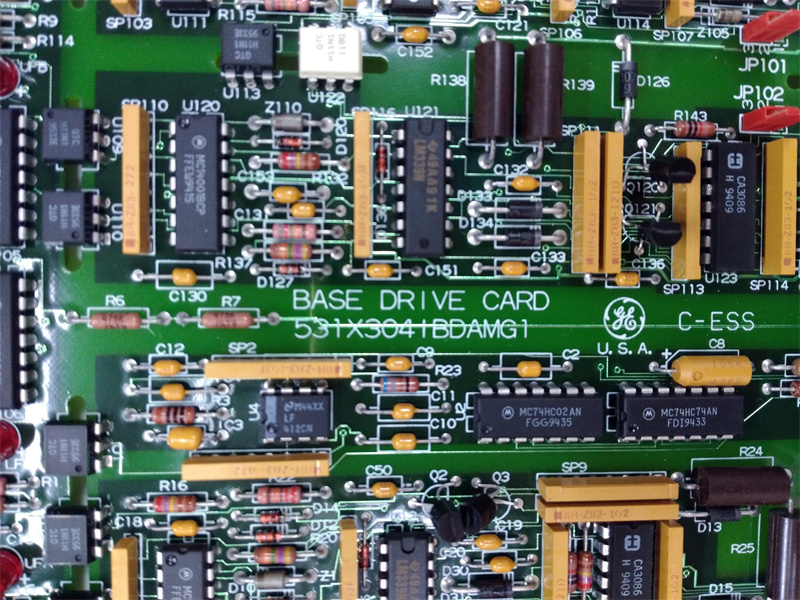

531x304ibdarg1 f31x304ibdamg1-00609

Thermal relay is generated by the current flowing into the thermal element to generate heat, so that there are different coefficients of expansion of the bimetal plate deformation, when the deformation reaches a certain distance, it will push the connecting rod action, so that the control circuit is disconnected, so as to make the contactor de-energized, the main circuit is disconnected, to achieve the overload protection of the motor. Relay as motor overload protection element, with its small size, simple structure, low cost and other advantages in production has been widely used.

Thermal relays are protection appliances used for overload protection of electric motors or other electrical equipment and electrical circuits.

In the actual operation of the motor, such as dragging the production machinery for the work process, if the machinery appears abnormal conditions or circuit abnormalities so that the motor meets the overload, then the motor speed will drop, the current in the winding will increase, so that the temperature of the winding of the motor rises. If the overload current is not large and the overload time is short, the motor winding does not exceed the allowable temperature rise, this overload is allowed. But if the overload time is long, the overload current is large, the temperature rise of the motor winding will exceed the permissible value, so that the motor winding aging, shorten the service life of the motor, and in serious cases, even the motor winding burned. Therefore, this overload is the motor can not withstand. Thermal relay is to utilize the principle of thermal effect of electric current, cut off the motor circuit when there is an overload that the motor can not withstand, to provide overload protection for the motor protection of the protection appliances.

The role of the thermal relay is: mainly used for overload protection of asynchronous motors, his working principle is that the overload current through the thermal element, so that the bimetal heating and bending to promote the action mechanism to drive the contact action, so that the motor control circuit is disconnected to achieve the motor cut off the thermal relay to stop the motor and play a role in overload protection. In view of the bimetal heating bending process, the transfer of heat takes a long time.

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: