Description

、:

Product Details:

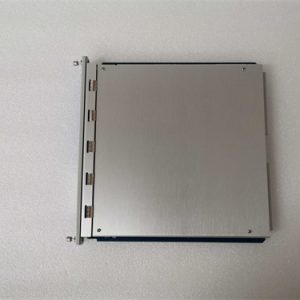

Model Number: 330106-05-30-10-02-00

Manufacturer: Bently Nevada (A GE Measurement & Control Solutions Brand)

Series: Bently 3300 XL

Description: An electromagnetic vibration sensor designed for precision measurement and monitoring of rotating machinery.

Specifications & Parameters:

Sensor Type: Electromagnetic (eddy current) vibration sensor

Measurement Range: Suitable for measuring vibrations in a wide range of frequencies

Sensitivity: 7.87V/mm (200mV/mil) for precise vibration detection

Output Type: Voltage output for easy integration into monitoring systems

Installation Type: Panel mount for secure installation

Operating Temperature: Optimized for operation at 25°C

Compliance: Meets API 670 standards for mechanical configuration, linear range, accuracy, and performance

Product Parameters:

Probe Design: Reverse mount probe with 8mm system for advanced performance

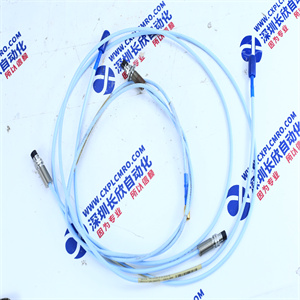

Interchangeability: Full interchangeability with extension cables and preamplifier sensors for easy maintenance and upgrades

Temperature Stability: Excellent temperature stability for reliable performance in varying environmental conditions

Application Fields:

Power Generation: Used in turbines, generators, and other rotating machinery for vibration monitoring and predictive maintenance

Oil & Gas Industry: Critical for safety and reliability in turbines, pumps, and compressors

Heavy Industries: Widely applied in steel, metallurgy, chemicals, and petrochemicals for vibration analysis and machinery protection

Automation & Control Systems: Integrated into automation and control systems for real-time monitoring and fault detection

The Bently Nevada 330106-05-30-10-02-00 electromagnetic vibration sensor is a precision instrument designed for accurate measurement and monitoring of vibrations in rotating machinery. Its specifications and parameters, including high sensitivity, voltage output, and compliance with industry standards, ensure reliable performance in various industrial settings. The sensor’s application in power generation, oil and gas, heavy industries, and automation systems demonstrates its versatility and importance in maintaining the safety and efficiency of rotating machinery.

Please note that specifications and parameters may vary slightly depending on the specific configuration and version of the product. It is recommended to consult the manufacturer’s official documentation or contact technical support for the most accurate and up-to-date information.

本特利 330106-05-30-10-02-00

本特利 330106-05-30-10-02-00

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: