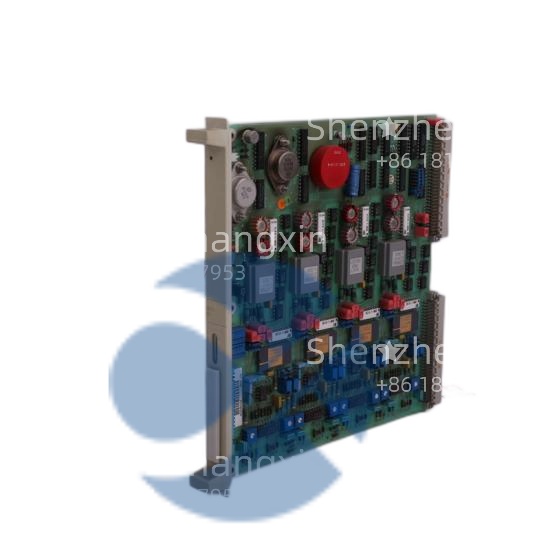

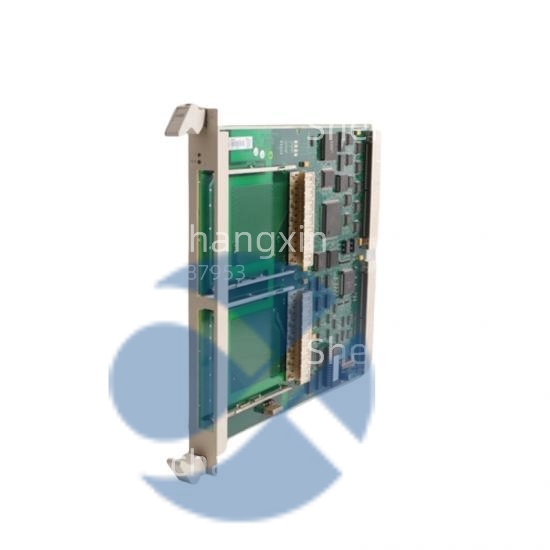

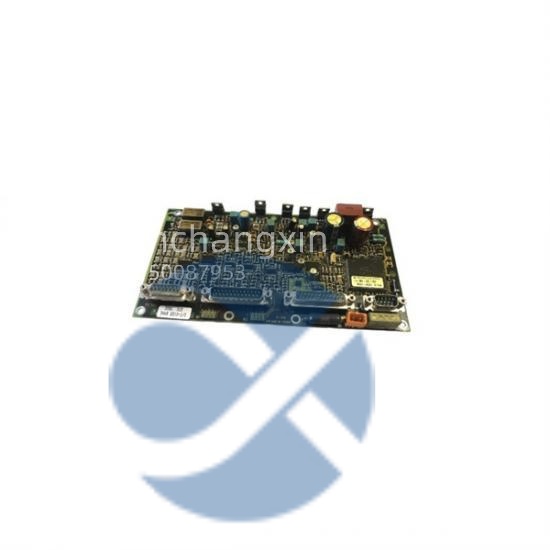

ABB SC520 3BSE003816R1 High-Performance Controller: The Brain for Critical Process Automation

Product Description The ABB SC520 3BSE003816R1 is a high-performance, scalable Programmable Automation Controller (PAC) manufactured by ABB, a global leader in industrial automation and digitalization. This controller is a central processing unit (CPU) module within ABB’s renowned AC 800M controller family, designed as the computational heart for the Extended Automation System 800xA. It executes complex…

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: