TRICONEX 4351B is a high-performance,fault-tolerant programmable logic controller(PLC)designed for critical control and safety applications.The following is a detailed introduction to TRICONEX 4351B:

I.Product Overview

As an important component of the TRICONEX control system,TRICONEX 4351B is responsible for realizing data communication between components within the system.It uses advanced hardware technology and reliable software design to ensure the real-time and accuracy of data communication.

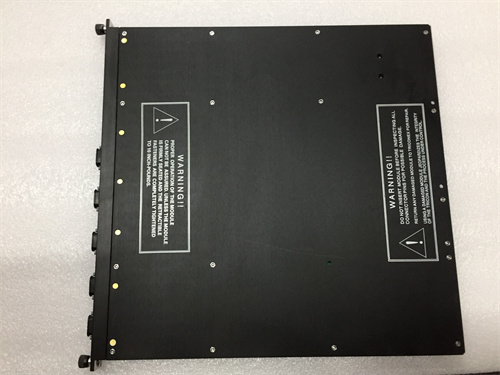

TRICONEX 4351B

II.Main Features

High-performance processor and large-capacity memory:

Adopts a 32-bit processor with a main frequency of 33MHz,which ensures efficient logic operation and data processing capabilities.

Equipped with 1MB RAM and 4MB flash memory,it can store more programs and data and support more complex control logic.

Multiple I/O interfaces:

Provides multiple I/O interfaces such as analog,digital,serial,Ethernet,etc.,which are convenient for connection and communication with various sensors and actuators.

Redundant architecture:

Adopts a three-module redundant(TMR)architecture,that is,three completely independent processors execute the same logic simultaneously.This redundancy ensures high availability and fault tolerance of the system,and the system can still operate normally even when a processor fails.

Programmability:

Supporting programmable functions,users can write control logic and safety rules according to specific application requirements.Use specific programming languagesto configure and customize the controller to meet various industrial control needs.

Compatibility:

Compatible with other products and systems of TRICONEX,it can be integrated with TRICON and TRIDENT systems to achieve a complete control and safety system.

Fault detection and alarm:

It has a fault detection mechanism that can monitor communication failures in real time and generate alarms and notifications when necessary.This helps to detect potential problems in time and avoid accidents.

High reliability design:

Adopting high reliability design and materials,it can operate stably in harsh industrial environments.

III.Application fields

TRICONEX 4351B is widely used in various industrial automation and control system application scenarios,including but not limited to:

Oil and gas:used for automation and control of oil and gas production,transportation and processing processes to ensure the safety and efficiency of production lines.

Chemical Industry:Monitor and control chemical reactions,mixing,separation and transmission processes in chemical plants and process units to ensure product quality and plant safety.

Power Industry:In power plants and power distribution systems,it is used to monitor power generation and transmission processes and ensure the reliability and stability of power systems.

Pharmaceutical Industry:In pharmaceutical production,it is used to automate drug production processes to ensure production compliance and quality control.

Food and Beverage Industry:In food processing and packaging processes,it is used to control production lines to ensure product safety and consistency.

Railway and Transportation:In railway signal control and traffic systems,it is used to ensure the safe operation of trains and traffic systems.

Water Treatment:In water treatment plants,it is used to monitor and control water quality,water pressure and water flow to ensure the normal operation of water supply systems.

Manufacturing:It is used in various manufacturing plants for automated production processes,machine control and quality inspection.

In addition,TRICONEX 4351B is also suitable for the nuclear industry,aerospace and other fields to monitor and control key processes such as nuclear reactions,spacecraft and ground station systems.

TRICONEX 4351B

4.Product Advantages

Real-time data transmission:It can quickly process input signals and control output signals in real time,suitable for systems that require fast response and precise control.

Easy to maintain and upgrade:The modular design makes installation,maintenance and expansion easier.Users can add or replace modules as needed,reducing maintenance costs and time.

Multiple communication protocol support:Supports multiple communication protocols such as Modbus,DNP3,OPC,etc.to ensure interoperability with different devices and systems.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: