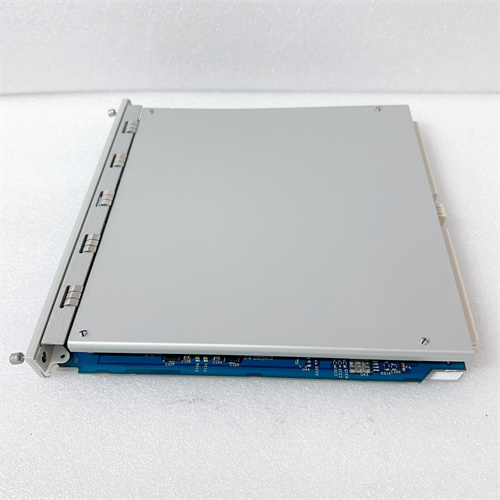

BENTLY 3500/22M 288055-01 is a transient data interface module(TDI)produced by Bently Nevada.The following is a detailed introduction to the module:

I.Product Overview

The BENTLY 3500/22M 288055-01 module is an important part of the Bently Nevada 3500 monitoring system.As an interface between the 3500 monitoring system and GE’s System 1®machinery management software,it realizes seamless data transmission and interaction.The module combines the functions of the 3500/20 rack interface module(RIM)and the data collection capabilities of a communication processor(such as TDXnet).It can continuously collect steady-state and transient waveform data and transmit this data to the host software via an Ethernet link.

II.Main Features

High-precision vibration monitoring:

The module has high-precision vibration monitoring functions and can monitor the vibration of the equipment in real time,including parameters such as vibration velocity,acceleration and displacement.

By collecting and analyzing vibration data,potential equipment failures and problems can be discovered in time,providing important reference information for equipment maintenance and care.

Fault diagnosis and early warning:

The module can identify and diagnose mechanical faults,such as bearing wear,imbalance,looseness,etc.,and issue alarms or trigger maintenance operations in time.

BENTLY 3500/22M 288055-01

Static data capture is a standard configuration of TDI,and dynamic or transient data can also be captured using an optional channel-enabled disk.

High reliability and stability:

The module has high reliability and stability and is suitable for long-term operation in industrial environments.

It can effectively monitor and protect the operating status of key equipment and ensure the continuity and stability of the production process.

Flexible configuration:

The module provides a variety of configuration options that can be customized according to specific application requirements,including the number of input channels,sampling rate,alarm settings,etc.

This allows the module to flexibly adapt to the needs of various industrial automation and control systems.

Rich communication interfaces:

The module has a variety of communication interfaces to support data interaction and integration with other monitoring systems or control systems.

This allows it to be easily integrated into existing industrial automation systems and improve the overall efficiency and reliability of the system.

BENTLY 3500/22M 288055-01

Modular design:The module supports modular design and can be combined with other Bently Nevada monitoring modules to build a more comprehensive monitoring system.This provides users with more choices and flexibility to meet monitoring needs in different scenarios.3.Application areas The BENTLY 3500/22M 288055-01 module is widely used in various industrial fields that require high-precision vibration monitoring and mechanical fault diagnosis,such as:Power industry:used to monitor the vibration of generators,turbines,pumps and fans.Oil and gas industry:used to monitor the vibration status of compressors,pumps and pipelines.Chemical industry:used to monitor the vibration of pumps,compressors and mixers.Manufacturing industry:used to monitor the vibration status of machine tools,robots and conveyors.4.Technical specifications(partial)Model:BENTLY 3500/22M 288055-01 Function:Transient Data Interface Module(TDI)Data collection and transmission:It can continuously collect steady-state and transient waveform data and transmit these data to the host software through an Ethernet link.Vibration monitoring:With high-precision vibration monitoring function,it can monitor the vibration of the equipment in real time.

Communication interface:Supports multiple communication interfaces to facilitate data exchange and communication with other devices or systems.

Installation location:Runs in the RIM slot of the 3500 rack with M series monitors(such as 3500/40M,3500/42M,etc.).

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: