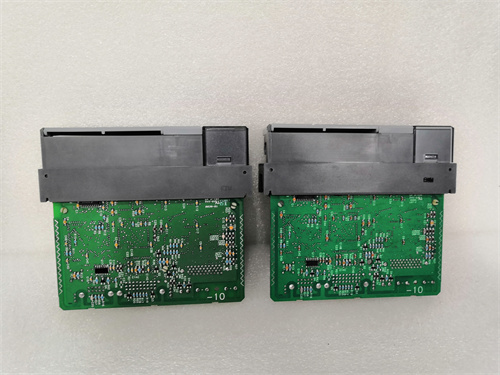

1747-L552 is a controller module produced by Rockwell Automation.Here is a detailed analysis of the module:

1.Basic attributes

Brand:Allen-Bradley,a brand of Rockwell Automation.

Model:1747-L552.

Category:SLC 500 series processor,belonging to the SLC 5/05 subcategory.

AB 1747-L552

2.Technical specifications

Processor type:Single-slot processor that can be directly connected to the backplane of any SLC 500 chassis.

I/O capacity:IO capacity with 4096 inputs and outputs,allowing the processor to control multiple small processes or a single large process.

Memory:Maximum user memory is 32K words,of which 28K words are used for data or programs and 4K words are used for user data.

Communication interface:Integrated RS232 port for point-to-point communication;supports Ethernet communication for networking applications and synchronous data exchange.

Instruction set:Supports up to 107 programming instructions.

Expandability:Allows installation of up to 3 chassis with up to 30 slots;supports the implementation of remote I/O topology to allow strategic installation of I/O modules.

Analog Points:Has a maximum of 480 local analog points.

Power and Current:Maximum input current is 1A at 5V DC and 0A at 24V DC.

Performance Parameters:

Typical Program Scan Time:0.9ms/K.

I/O Scan Time:0.225ms.

XIC Bit Execution Time:0.37us.

Program Scan Retention Time after Power Failure:20ms to 3s depending on power supply load.

Environmental Parameters:

Operating Temperature Range:0 to 60 degrees Celsius.

Storage Temperature Range:-40 to 85 degrees Celsius.

Operating Vibration:0.015 inches.

Peak-to-Peak Displacement:57 to 57 Hz.

Acceleration:2.5G to 57 Hz.

Operation Shock:30G.

Relative humidity:5%to 95%(non-condensing).

AB 1747-L552

3.Functions and applications

Main functions:Realize logic control and data processing,suitable for various industrial automation and control systems.

Application scenarios:Due to its high-performance processor and algorithm,it can quickly and accurately execute control logic,so it is very suitable for medium to large applications,especially for application scenarios that require the integration of machine-level areas into enterprise-level applications.

Interfaces and connections:It provides a variety of different input and output interfaces,including digital input and output,analog input and output,communication interfaces,etc.,which can seamlessly connect and exchange data with other devices and systems.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: