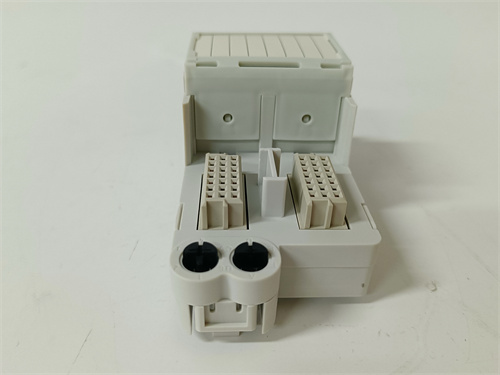

8610-FT-NA may refer to a dedicated connection solution from an industrial control gas turbine module or PLC(Programmable Logic Controller)to a database produced by companies such as General Electric(GE)or Eaton(EATON).The following is a detailed introduction to 8610-FT-NA:

I.Product Overview

Purpose:

As an industrial control gas turbine module,8610-FT-NA is usually used to control the start,operation and shutdown of the engine,and manage various operating modes of the engine,such as automatic start and stop and emergency shutdown.

As a connection solution from PLC to database,8610-FT-NA is used to connect the PLC in the factory workshop to the SQL database or cloud storage to achieve real-time data transmission and processing.

Manufacturer:This product may be produced by well-known manufacturers such as General Electric(GE)or Eaton(EATON),depending on market supply and sales channels.

8610-FT-NA

II.Product Features

Engine control function(for gas turbine modules only):

Speedcontrol:Ensure that the engine maintains a stable operating speed under different loads.

Load management:Optimize the load of the engine to ensure that it runs at optimal efficiency.

Fuel management:Monitor and control fuel supply to ensure that the engine receives the proper fuel.

Fault diagnosis and remote monitoring:

The 8610-FT-NA module can detect and report engine faults and abnormal conditions,allowing operators to monitor and control the operating status of the engine through a network or remote connection.

Data logging and reporting:

Record key performance data for subsequent analysis and report generation.

PLC to database connection(for specific solutions):

The 8610-FT-NA provides a dedicated PLC to database connection solution for a variety of industrial automation projects,such as tracking and tracing,quality monitoring,production indicator monitoring,etc.

8610-FT-NA

3.Application areas

Industrial automation:8610-FT-NA is widely used in various industrial automation control systems,such as power,petrochemical,food processing and other industries.

Data management and analysis:As a PLC to database connection solution,8610-FT-NA is suitable for scenarios where large amounts of real-time data need to be transferred from the PLC to the database for storage and analysis.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: