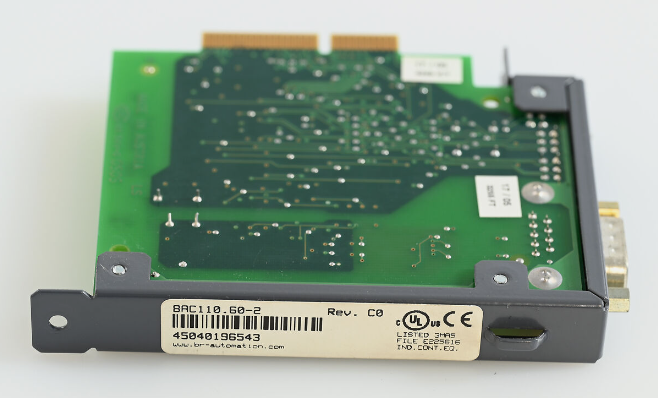

B&R 8AC120.60-1 Product Detailed Introduction

Product Overview

B&R 8AC120.60-1 is an encoder interface module produced by B&R Automation. It is mainly used to connect incremental encoders and convert the digital signals of the encoders into signals that can be processed by PLC. It is often used in servo drive systems to obtain the position feedback information of the motor shaft.

Main Functions

Encoder Interface: Provides a standard encoder interface and supports multiple encoder protocols.

Signal Conversion: Converts the digital signal of the encoder into a digital signal that can be processed by PLC.

Signal Filtering: Built-in filtering function to improve the anti-interference ability of the signal.

Multi-channel: Multiple encoders can be connected at the same time.

Application Scenarios

Servo Drive System: Used to obtain the position feedback information of the motor shaft and realize closed-loop control.

Motion Control System: Used to achieve high-precision motion control.

Automated Production Line: Used to monitor and control the position of the robot.

Product Features

High Precision: With high measurement accuracy, it can meet the needs of high-precision motion control.

High Reliability: Adopts industrial-grade design with good anti-interference and stability.

Flexible configuration: Flexible configuration through software to adapt to different application requirements.

Easy to integrate: Seamless integration with B&R PLC, convenient system construction.

Technical parameters (typical values)

Input signal: Incremental encoder signal

Output signal: Digital signal

Interface type: EnDat 2.1

Operating voltage: 24V DC

Operating temperature: 0℃~55℃

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: