Description

Product Description:

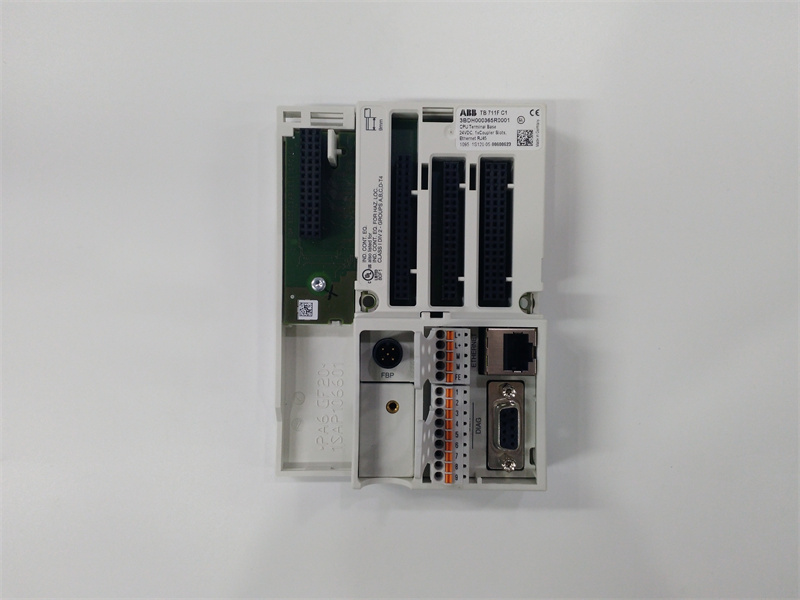

TB711FC1 3BDH000365R0001 is a high performance inverter manufactured by ABB. The inverter adopts advanced motor control technology, which can precisely control the speed and torque of the motor and is suitable for various industrial automation and motion control applications.

Product Parameters:

Input voltage range: usually single-phase or three-phase AC power supply with voltage range of 200-240V or 380-460V, etc.

Output Frequency Range: Adjustable range usually in 0-400Hz.

Rated output current: varies according to model and power level, which can meet the needs of different loads.

Control accuracy: high accuracy of speed and torque control, can realize precise position control.

Communication interface: Supporting a variety of communication protocols, such as Modbus, Profibus, Profinet, etc., which is easy to integrate into industrial automation systems.

Product specification:

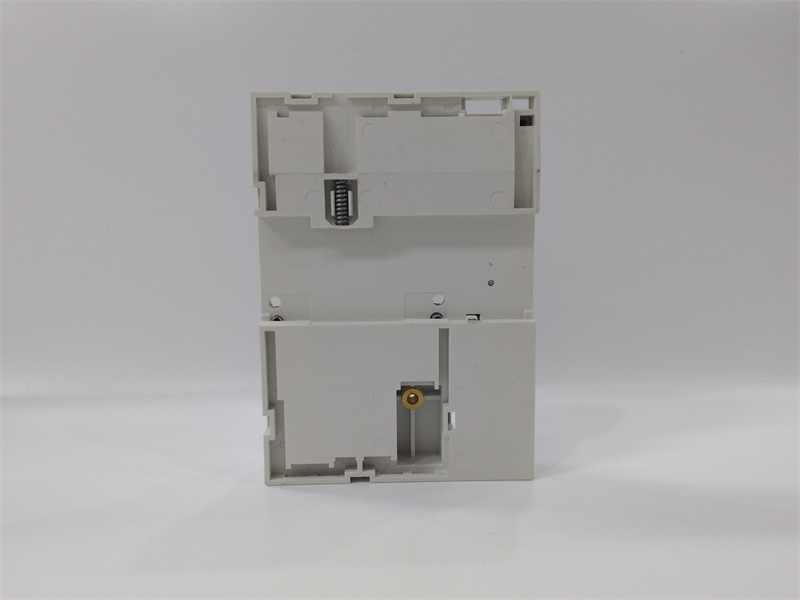

Size: Depends on model and configuration, usually small or medium-sized devices.

Weight: Depending on model and configuration.

Cooling: Built-in heat sink or fan cooling, etc. to ensure stable operation for a long time.

Product Features:

High performance: Adopts advanced motor control algorithms for fast response and high-precision control.

Easy Programming and Debugging: Provide friendly user interface and easy-to-use programming tools to facilitate programming and debugging.

Reliability: Strict quality control and testing to ensure stable and reliable operation under various application conditions.

High degree of integration: Supports a variety of communication protocols for easy integration with other devices or controllers.

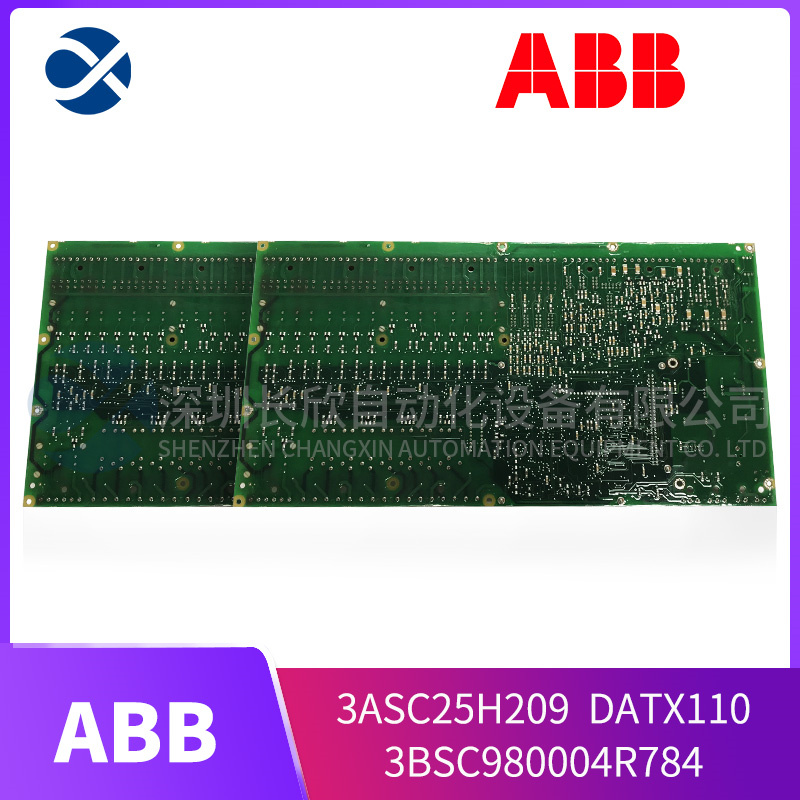

Expandability: Different function modules or expansion cards can be configured as needed to meet the needs of different applications.

Application areas:

TB711FC1 3BDH000365R0001 ABB is widely used in various industrial automation and motion control fields, such as textile, packaging, printing, electronic manufacturing, food and beverage industries. It can be used to control parameters such as speed, position and torque of motors for precise processing and automated production. In addition, this frequency converter can also be applied in the fields of energy saving and energy management to improve the energy utilization efficiency of equipment and reduce production costs.

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: