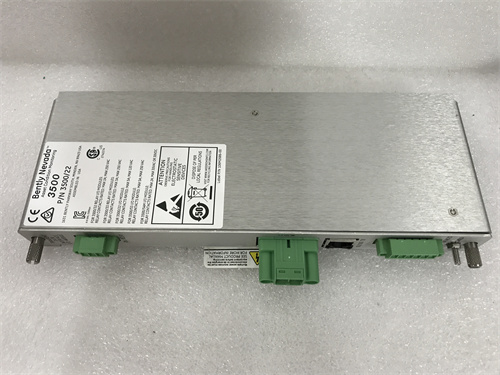

BENTLY 3500/22M is a transient data interface module developed by Bently Nevada.The following is a detailed introduction to it:

1.Product Overview

The BENTLY 3500/22M transient data interface module is part of the Bently Nevada monitoring and control system product line,and is commonly used for monitoring,fault diagnosis and performance optimization of industrial equipment.The module can continuously collect steady-state and transient dynamic(waveform)data and transmit these data to the host software through an Ethernet link.、

2.Main Features

Powerful data processing capabilities:BENTLY 3500/22M is equipped with a high-performance processor and memory,which can handle large amounts of data and complex control algorithms,and improve control accuracy and response speed.

Rich communication interfaces:The module supports a variety of different communication interfaces,such as Ethernet,serial port,CAN bus,etc.,which is convenient for communication and control with various devices.

Flexible programming methods:BENTLY 3500/22M supports a variety of programming languagesand development environments.Users can choose the appropriate programming language for programming and control according to their needs.

High reliability and long life:The module adopts high-quality materials and design,has the characteristics of high reliability and long life,and can meet the high requirements of reliability and stability in the field of industrial automation.

Easy to operate and maintain:BENTLY 3500/22M has a simple and easy-to-use interface and operation mode,which is convenient for users to set up,debug and use.At the same time,the module also supports automated maintenance and repair functions to reduce maintenance costs.

III.Functional application

Vibration monitoring:BENTLY 3500/22M can be used to monitor the vibration of industrial equipment(such as engines,pumps,and fans).Vibration data can be used to predict the health of equipment and help prevent equipment failure.

Mechanical equipment health monitoring:By monitoring the transient data of mechanical equipment,the working status of the equipment can be evaluated,potential problems can be discovered and solved in time,and the reliability and life of the equipment can be improved.

Transient event recording:This module can be used to record and analyze transient events that occur in the equipment,such as sudden voltage changes,shocks,or other unusual working conditions.This is very important for understanding unusual conditions during equipment operation and fault diagnosis.

Power system monitoring:In the power industry,BENTLY 3500/22M can be used to monitor parameters such as current,voltage and frequency in the power system,which helps to ensure the stable operation of the power system.

Factory automation:The module can be integrated into the factory automation system for real-time monitoring of the operating status of production equipment,thereby improving production efficiency and quality.

BENTLY 3500 22M

IV.Technical parameters

Some of the main technical parameters of the BENTLY 3500/22M transient data interface module may include(specific parameters may vary depending on product version and configuration):

Operating voltage:Usually 24V DC.

Operating current:Under a specific voltage,the operating current has a maximum limit.

Communication interface:Supports multiple interfaces such as Ethernet,serial port,CAN bus,etc.

Data processing capability:It has a high-performance processor and sufficient memory to handle large amounts of data and complex algorithms.

Storage capacity:The memory capacity of the module determines the number of transient events that can be collected.

V.Installation and configuration

Installation location:In a 3500 rack,the BENTLY 3500/22M is usually located in the slot next to the power supply and always occupies slot 1.

Configuration method:It can be configured through programming mode,supporting remote and local configuration.After configuration is completed,it can be switched to running mode to prevent unnecessary configuration changes.

BENTLY 3500 22M

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: