Description

9907-167 usually refers to a steam turbine digital speed governor of the WOODWARD brand.The following is a detailed introduction to the product:

1.Basic information

Brand:WOODWARD

Model:9907-167

Type:Steam turbine digital speed governor

2.Product features

High-precision control:The advanced PID control algorithm can achieve precise control of the speed with an accuracy of up to±0.25%,meeting the needs of various complex working conditions.

High stability and fast response:It can adapt to different types of steam turbines and operating environments,ensuring the stable operation of the steam turbine and precise control of the output power.

Easy to use:It provides an intuitive user interface,and users can easily view and set parameters through the LCD display on the front panel.Supports multiple communication interfaces(such as RS-485,etc.),which is convenient for users to integrate with other systems.

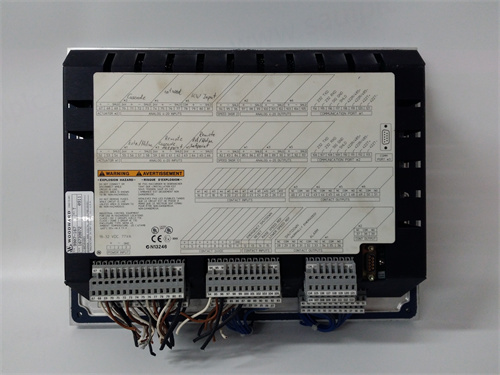

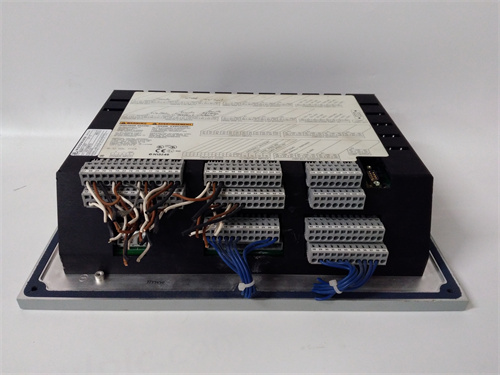

WOODWARD 9907-167

Efficient and durable:It adopts a rugged design and uses high-quality components to operate reliably in harsh environments.Its wide operating temperature range is-40°C to+85°C,and its shock,dust and waterproof rating is up to IP67,ensuring that the equipment can work properly under various extreme conditions.

High immunity:It is highly immune to electrical interference on the power supply and can maintain stable performance in complex electromagnetic environments.

III.Application areas

Cogeneration:In the cogeneration system,it is used to control the speed and output power of the steam turbine to meet the power generation and heating needs.

Power plant:As the core control component of the steam turbine,it ensures the stable operation and efficient power generation of the generator set.

Industrial field:In the chemical,metallurgical,papermaking and other industrial fields,it is used to control the speed and output power of various rotating machinery.

Marine power system:It is used to control the speed and output power of the ship’s main engine to ensure the navigation safety and performance of the ship.

WOODWARD 9907-167

IV.Operation and maintenance

Installation and connection:Install the speed governor to the control cabinet or operating platform near the steam turbine,and connect the sensors and actuators according to the instructions to ensure correct signal transmission and action execution.

Power supply and communication:Provide the required power to the speed governor,and use the appropriate communication interface to connect the speed governor to the host computer or monitoring system.Ensure the correct configuration and parameter setting of the communication interface.

Parameter setting:Set the control parameters of the speed governor,such as target speed,start and stop speed,acceleration and deceleration,etc.,according to the turbine model,operation requirements and control system requirements.

Control program writing:Use supported programming languages(such as C++,C#,etc.)to write the control program,and realize the control and operation of the speed governor according to the actual control logic and algorithm.Ensure the correctness and stability of the control program.

Program download and debugging:Download the written control program to the speed governor,and debug and test it to ensure that the speed governor can operate normally according to the preset control logic and parameters,and can correctly respond to the state changes and operation requirements of the turbine.

Operation and maintenance:Start the turbine and control system,and run the speed governor.During the operation,pay close attention to the operating status and parameter changes of the speed governor,and adjust and control the speed and output power of the turbine in time.At the same time,regular maintenance and care are also important measures to ensure the normal operation and service life of the speed governor.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: