Description

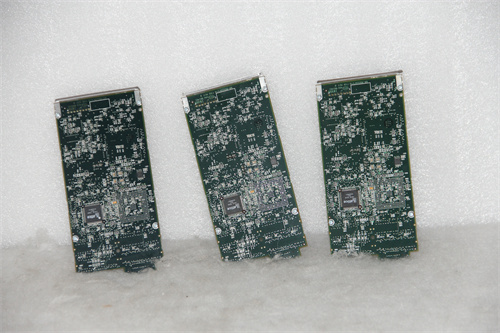

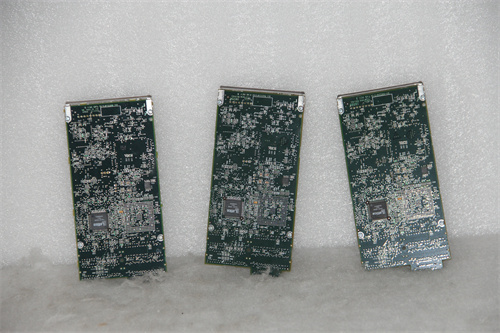

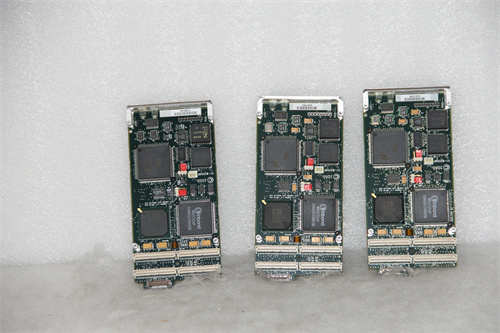

IPMC7616E-002 is a motor control integrated circuit designed by Motorola.The following is a detailed introduction to it:

1.Basic parameters

Model:IPMC7616E-002

Input voltage:100~240V AC

Output voltage:12V DC

Output power:76W

Efficiency:greater than 90%

Motorola IPMC7616E-002

2.Performance characteristics

Wide operating voltage range:IPMC7616E-002 has a wide input voltage range and can cope with motor control requirements under different voltage conditions.

High motor current and low on-resistance:This makes the integrated circuit perform well in motor control applications and can drive the motor efficiently.

High performance:IPMC7616E-002 adopts advanced control technology and design to provide high-performance motor control functions to meet the needs of various complex application scenarios.

High stability:The integrated circuit is designed to have a high degree of stability to ensure that the equipment in the motor control system obtains a stable power supply,thereby improving the overall stability of the system.

Flexibility:IPMC7616E-002 supports a variety of different control methods and algorithms,and can be flexibly configured and expanded according to different application scenarios and requirements,providing users with more choices.

Safety:Motorola is a manufacturer known for its industrial safety systems,so IPMC7616E-002 also has a high degree of safety functions to ensure the reliability of motor control systems and comply with relevant safety standards.

Motorola IPMC7616E-002

III.Physical properties

Thermal resistance(junction to ambient):50°C/W

Maximum junction temperature:150°C

Storage temperature range:-40°C to 150°C

Operating temperature:-40°C to 70°C

Package type:SOIC-28

Moisture sensitivity level:3

RoHS compliant:Yes

IV.Application scenarios

IPMC7616E-002 is commonly used in industrial automation control systems and can meet the needs of different industrial automation application scenarios.It can be used to drive various motors,such as DC motors,AC motors,etc.,to achieve precise motor control functions.At the same time,the integrated circuit also supports remote monitoring and control functions,which is convenient for users to carry out maintenance and troubleshooting.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: