Description

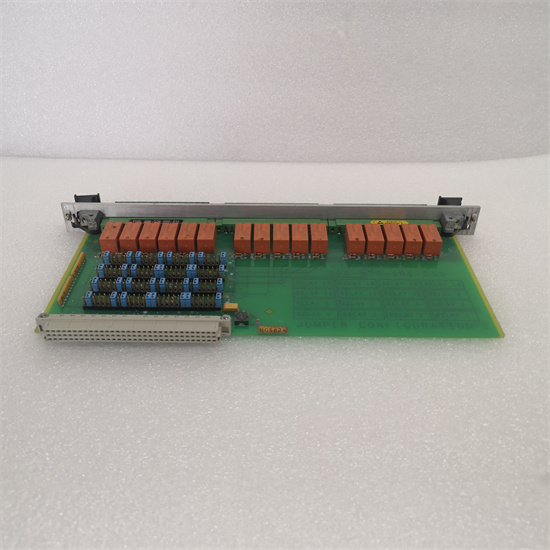

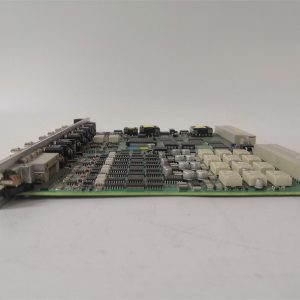

Vibro-meter VM600 MPC4 is a high-precision mechanical protection card or vibration monitoring instrument.The following is a detailed introduction to the product:

I.Product Overview

Vibro-meter VM600 MPC4 is the core component of the VM600 series mechanical protection system(MPS)produced by Vibro-Meter(now Meggitt).It uses advanced digital signal processing technology(DSP)to monitor the vibration of the machine in real time to ensure the normal operation of the machine.The protection card can simultaneously measure and monitor up to four dynamic signal inputs and two speed inputs,such as acceleration,speed and displacement(approach)signals,and is suitable for monitoring vibration,bearing conditions,mechanical operating conditions,etc.of various rotating machinery.

II.Main features and advantages

Multi-channel monitoring:

VM600 MPC4 has 4 dynamic signal channels and 2 speed(speed)channels,which can be programmed separately,support multi-channel data acquisition,and can monitor multiple points at the same time to improve monitoring coverage.

Advanced digital signal processing technology:

Adopt the latest DSP technology to achieve real-time measurement and monitoring,provide high-resolution measurement and real-time response,and ensure the safety of key equipment.

Programmability and flexibility:

Programmable wideband and narrowband filters,monitoring both amplitude and phase.

Programmable alarm,danger and deterministic set points,adaptive alarm and danger levels.

Supports a wide range of signal processing functions such as digital filtering,integration or differentiation,rectification(RMS,average,true peak or true peak-to-peak),order tracking(amplitude and phase)and measurement of sensor-to-target gap.

Vibro-meter VM600 MPC4

Integrated power supply and interface:

Integrated power supply for sensors and signal conditioners such as IEPE accelerometers and proximity measurement systems.

Front panel BNC connector for easy analysis of buffered“raw”sensor signals.

Available in“standard”,“isolated circuit”and“safety”(SIL)versions to meet different application requirements.

High reliability and stability:

The MPC4 performs self-test and diagnostic routines at power-up.

The built-in“OK system”continuously monitors the signal levels provided by the measurement chain(sensor and/or signal conditioner)and displays any problems caused by broken transmission lines,sensor or signal conditioner failures.

Communication and integration:

Supports communication with host computers and DCS/PLC systems for centralized management and analysis.

The design of VM600 rack,mechanical protection card,condition monitoring card and related software complies with the isolation requirements of mechanical protection system(MPS)and condition monitoring system(CMS)of API670 standard,ensuring that the function of MPS does not depend on the operation of CMS and will not be affected by the operation of CMS.

Vibro-meter VM600 MPC4

III.Application fields

VM600 MPC4 is widely used in the field of vibration monitoring and fault diagnosis of rotating machinery in the power,petroleum,chemical,steel,cement and other industries.It is suitable for real-time monitoring and protection of the operating status of industrial equipment,such as vibration monitoring and protection of turbines and generators,real-time monitoring and fault diagnosis of compressors,pumps and drilling equipment,and status monitoring of high-speed centrifuges and mixing equipment.

4.Product parameters and specifications

Input channels:4 channels

Frequency range:0.5Hz to 10kHz

Measurement range:0.1mm/s to 50mm/s

Data sampling rate:256 times per second

Operating temperature:-20°C to 60°C

Storage capacity:10,000 data points

Supply voltage:24VDC

Dimensions:210x170x75mm

Weight:1.5kg

Protection level:IP20

Signal input:BNC connector

Communication interface:RS-485(there may be other communication interfaces,depending on the product version and configuration)

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp / Wechat:+86 18150087953 / +86 18005022138

WhatsApp / Wechat:+86 18150087953 / +86 18005022138 Email:

Email: