Description

CACR-02-TE1K is a driver,usually produced by YASKAWA.Here is a detailed analysis of CACR-02-TE1K:

1.Product Overview

The CACR-02-TE1K driver is mainly used to control servo motors or stepper motors to provide precise position and speed control.This driver is widely used in automation,robotics and other motion control applications,and is praised for its high performance and reliability.

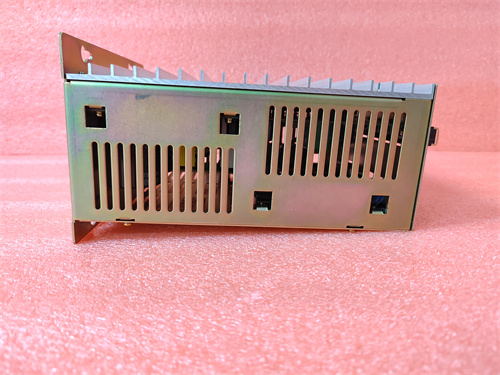

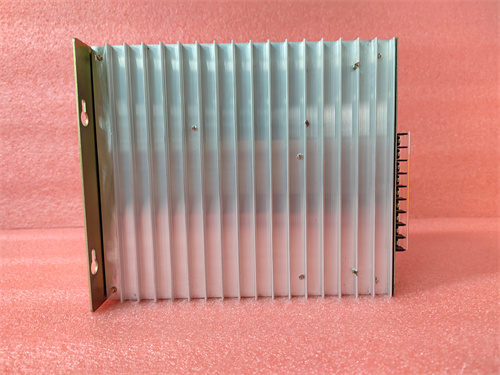

YASKAWA CACR-02-TE1K

2.Product Features

Servo control:The CACR-02-TE1K driver is able to provide high-precision position and speed control,especially suitable for applications such as robots,automation equipment and machine tools.

Stepper motor control:In addition to servo motors,this driver can also be used in stepper motor systems to achieve fixed-point control and precise movement.

Encoder feedback:Supports encoders or feedback devices to provide closed-loop control,thereby achieving higher control accuracy.

Protection function:The driver has multiple protection functions such as overcurrent protection,overheat protection,overvoltage protection,etc.to ensure the safety and reliability of the equipment.

Communication interface:Equipped with a communication interface,allowing communication with the controller or host system for remote monitoring and programming.

III.Product specifications

The specific specifications of CACR-02-TE1K may vary depending on production batches or customization requirements.But in general,its specifications may include:

Current capability:defines the output current range to accommodate motors of different types and sizes.

Input voltage range:The specific input voltage range that ensures the normal operation of the drive,which may include single-phase or three-phase power options.

Other specifications:such as size,weight,operating temperature range,etc.,these specifications are usually listed in detail in the product manual or technical documentation.

YASKAWA CACR-02-TE1K

IV.Application areas

CACR-02-TE1K drives are widely used in the following fields:

Industrial automation:Provides precise motion control in automated production lines and equipment.

Robotics:Provides high-precision position and speed control for robots to achieve complex motion trajectories.

CNC machine tools:Used to control the movement and positioning of tools in CNC machine tools.

Printing machinery:Used to control the delivery and positioning of paper in printing machinery.

Packaging equipment:Used to control the delivery and positioning of packaging materials in packaging equipment.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953

WhatsApp:+86 18005022363 WeChat: +86 18005022363 /+86 18150887953  Email:

Email: