Description

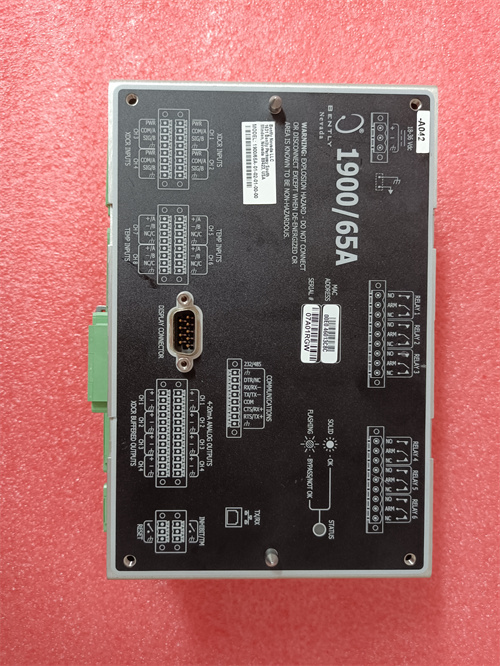

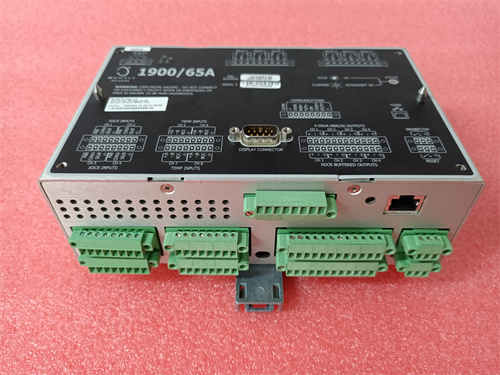

BENTLY 1900/65A-01-02-01-00-00 is a general-purpose equipment monitor produced by Bently Nevada.The following is a detailed introduction to the product:

1.Product Overview

This product is designed to provide continuous equipment status monitoring and is suitable for a variety of machines and processes that need to benefit from continuous monitoring.Its low cost and versatility make it an ideal general solution.

BENTLY 1900/65A-01-02-01-00-00

2.Main Features

Input and output configuration:

Four sensor inputs are provided,which can be used to connect accelerometers,velocity sensors or proximity sensors,etc.

Four temperature inputs are provided,supporting E,J,K and T type thermocouples and 2-wire or 3-wire RTDs.

Six relay outputs are provided,which can be used to perform various control tasks such as alarms,shutdowns,etc.

Four 4-20mA recorder outputs are provided,which can be used to send monitoring data to a recorder or data acquisition system.

Communication and Data Interface:

Supports Modbus communication protocol,allowing the monitor to communicate with clients such as distributed control systems(DCS),supervisory control and data acquisition(SCADA)systems,programmable logic controllers(PLCs),etc.

Provides Ethernet and RS232/485 serial communication interfaces to facilitate data exchange with various devices.

Configuration and Operation:

Users can use the 1900 configuration software to define monitoring operations and Modbus gateway register mapping.

The software allows users to configure data output based on OK,Alert,and dangerous status of any channel or channel combination.

The monitor supports optional display/keyboard to view channel information or make small configuration changes.

Installation and Expansion:

Supports DIN rail mounting or bulkhead mounting,allowing users to choose the appropriate installation method according to actual needs.

The monitor can be installed up to 75 meters(250 feet)away from the monitor module,allowing users to conduct remote monitoring.

BENTLY 1900/65A-01-02-01-00-00

3.Application Fields

BENTLY 1900/65A-01-02-01-00-00 Universal Equipment Monitor is widely used in various industrial fields,such as:

Equipment Health Monitoring:Used to monitor the status of rotating machinery(such as turbines,generators,pumps and compressors)to detect changes in vibration,temperature,pressure and other operating parameters to identify the health of the equipment.

Fault Diagnosis:Helps identify the failure mode of the equipment by monitoring the vibration and other signals of the equipment so that repair and maintenance measures can be taken in advance to reduce downtime.

Predictive Maintenance:Based on real-time monitoring data,analyze the equipment status,predict potential failures,and formulate maintenance plans based on the prediction results to maximize the service life of the equipment.

Safety and Reliability:Help ensure the safety and reliability of the equipment by monitoring the equipment status in real time to prevent accidents caused by possible equipment failures.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

WhatsApp / Wechat:+86 18150087953 / +86 18005022138

WhatsApp / Wechat:+86 18150087953 / +86 18005022138 Email:

Email: